When Process Engineers are looking for improvements for their site, Emission Control or handling Dust / Fume Emissions is only a small part of their day-to-day business. It’s demand for attention is rising, however with ever changing emission legislation, attention to healthy work environments or explosion safety. Lately, a lot of cost savings can be found by reducing energy consumption, recovering heat and by finding balanced operations, preventing over-extraction and wasting resources.

With the demand for effective emission control rising, so does the positioning of various solutions. JOA Air Solutions has deliberately chosen for a true tailor-made approach where we design solutions from scratch and start out with data collection and measurements, resulting in a pre-engineering study before coming up with the right solution.

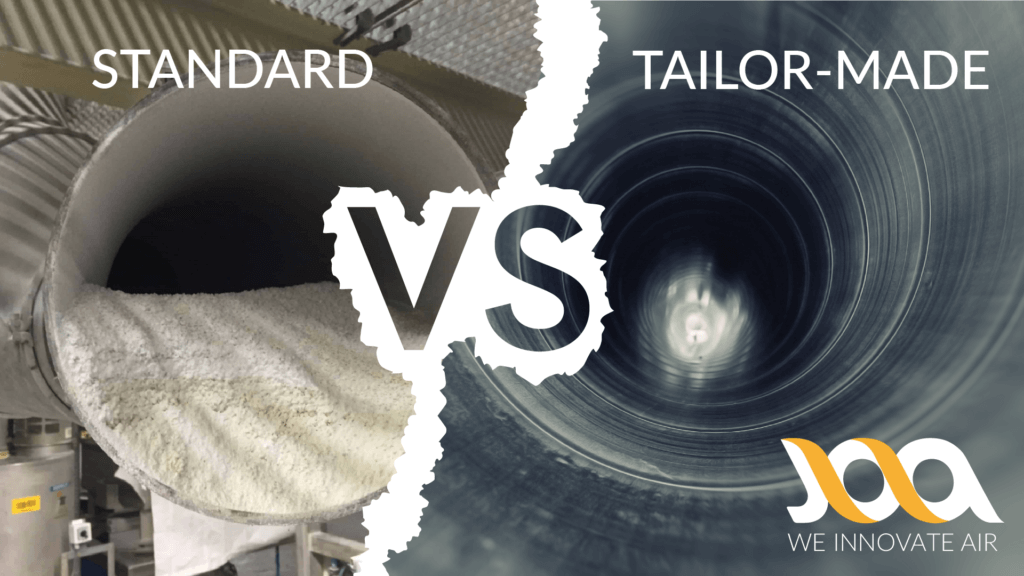

We find that many other suppliers state that they ‘listen to their clients’ and come up with ‘customized’ solutions, but in practice they only adjust or offer another sized standard solution. This is fine for smaller or less complex production processes. However, when things become complex or large in volume, a standard solution will not suffice.

1. Truly Tailor-made Emission Control Equipment: The Solution to Your Industry’s Pollution Woes

This brings us to the first main differentiator of JOA Air Solutions. With the increasing demand for more efficient and safer processes, tailor-made equipment has become a popular choice for Process Engineers. The advantages of tailor-made filtration equipment are numerous. First and foremost, it is designed specifically for the unique needs of a particular process, ensuring optimal performance and efficiency. It can also be customized to fit the available space and integrate seamlessly with existing equipment. Additionally, tailor-made equipment often includes innovative features that can improve safety and reduce energy consumption, leading to cost savings in the long run. Overall, investing in tailor-made equipment can provide a significant competitive advantage for companies looking to stay ahead of the curve in their industry.

Often, we come across manufacturers who have dealt with standard suppliers and their underwhelming solutions. They simply offer a quick fix without any regard for the specific requirements of the process. The responsibility then lies with the manufacturer to determine whether the solution is suitable for their needs. This lack of commitment and responsibility towards fulfilling special requests and guaranteeing results is a common concern for engineers.

2. Pre-Engineering Studies to really understand your site’s requirements

A true understanding of a production process is needed to come up with the best possible solutions. This is why we generally conduct a pre-engineering study in advance of engineering. Taking measurements and collecting data is essential to know what to prioritize and what scenarios must be considered.

We often receive requests to ‘send our catalogue’ or just give us a price, and we understand this is how you are used to work. However, to be able to properly service you and come up with the best solutions. Our proposed solution may differ depending on many variables, including: Volumes, Velocities, Extraction Points, Footprint Demand, Relative Humidity, Temperatures, Scenarios, Opportunities for Heat Recovery, Explosion Safety (ATEX) and other specifications coming from your unique production process.

Every Pre-Engineering Study is concluded with a quotation of the prize of our proposed solutions. Also, to identify bottlenecks and validate our findings, we make use of in-house developed Air Technical Modeling software.

3. Air Technical Modeling making the difference between knowing for sure and hoping for the best

While there are indeed a number of well-known names in the Emission Control, Industrial Air Filtration, and Pollution Prevention industry – including Donaldson, Camfil, Nederman, Freudenberg, and Mann+Hummel – even their vast experience may not be enough when it comes to more complex projects. Standard suppliers or machine builders may be limited in their abilities to provide customized solutions, often offering only quick and superficial proposals. This is where JOA Air Solutions stands out from the crowd, utilizing in-house developed Air Technical Modeling software and providing tailor-made equipment and thorough pre-engineering studies to offer customized solutions that optimize performance, improve safety, and reduce energy consumption.

JOA is unique in its approach by using in-house developed Air Technical Modeling software. It shows us where to improve. If emission sources should be eliminated or where and how we should extract at the source. It validates all our designed solutions so we can commit to future results and offer process guarantees.

Comparing standard vs. tailored Emission Control

In conclusion, when it comes to effective emission control solutions, in many cases a manufacturer can make use of standardized dust & fume extraction systems. Especially when volumes are low, emission points are limited and cost of resources are low, this is the case.

In the realm of complex and high-volume industrial processes, JOA Air Solutions shines through as a provider of tailored equipment, thorough pre-engineering studies, and in-house developed Air Technical Modeling software, setting it apart from the rest. With an emphasis on understanding each unique production process, JOA Air Solutions is able to offer customized solutions that optimize performance, improve explosion safety, and reduce energy consumption, ultimately providing a significant competitive advantage for companies in need of emission control solutions.