Why is it hard to improve manufacturing processes (Challenges)

You have enough to consider with the day-to-day running of operations without an additional factor to worry about.

Cost/investments. Process improvement is likely to require some investment. Is this perceived expense worth it – especially when things seem to be running ok?

Where to start? There are so many different approaches to process improvement, it can be difficult to decide which one is for you.

Lack of knowledge / capabilities

Lack of insights. We often need to explain what is possible when choosing a different, more data driven approach based on Air Technical Modeling

Why choose JOA

Clear plan to start improving

Besides designing, building and implementing equipment, we start with collecting data. Pre-engineering, site survey, etc.

Different approaches that can improve your site’s processes

- Pre-engineering study based on Air technical Modeling

- Masterplan to base priorities on hard data

- Quick Energy Screening – Know exactly what energy can be recovered

- Implement Energy Recovery Solutions to safe and reclaim energy

- Scrubbers that reduce energy usage

- Reduce maintenance efforts by Acoustic Cleaning in Place

- On-demand balanced extraction with automated air flow stabilization

- Patented & Proven Deflector Hoods & Bleeds to improve extraction

- Measuring Flows resulting in predictive maintenance

- Up to 2% yield improvement with Conveying Air Control Unit

- Preventing industrial fouling with Balancing Restrictors

5 Tips to improve your industrial process

Running a successful manufacturing operation today is a challenge. There are a lot of hurdles to overcome. Competition is fierce, materials are rising in price

and the economic climate is uncertain.

In conditions such as this, it is crucially important to have full control of your processes. Download the PDF to read the 5 tips to improve your industrial process:

Benefits

It is worth overcoming these challenges, however; the benefits that arise as a result provide an answer to each of the above and more besides.

- Improved economic performance by effective dust extraction

- Optimised energy efficiency

- Higher uptime and less maintenance needed

- Prevention of under or over extraction

The benefits of process improvement can be particularly attractive when you consider that there is expert help on hand to get you started and guide you through.

Secondary advantages

Aside from the economic benefits of process improvement, there are a number of additional gains to be made. These relate to, for example, complying with emissions and energy limits and ensuring a workplace is clean and safe. Optimal extraction, for example, minimizes the risk of explosion.

A process proven in action

The JOA approach has been designed to provide you with process improvement solutions tailored to your operations. Proven in action, it consists of the following steps to support you from start to finish:

The initial consultancy will provide the understanding of your processes that is required to improve them. Before we get underway with that, however, JOA carries out air technical modeling. This allows us to predict how our solutions will perform already in the pre-engineering phase, avoiding both over and under extraction and saving both time and money.

Every operation is different. This means that, to be fully effective, an industrial air filtration system must be tailor-made.

Once we’ve designed a solution dedicated entirely to your operational requirements, we are able to produce and install it, putting in place the process improvement that can bring the benefits described above. Improving processes is highly related to the other four industrial challenges we help solve for manufactures. These include:

That’s not the end, however, as JOA continues to provide support following installation, throughout the lifecycle of your solution.

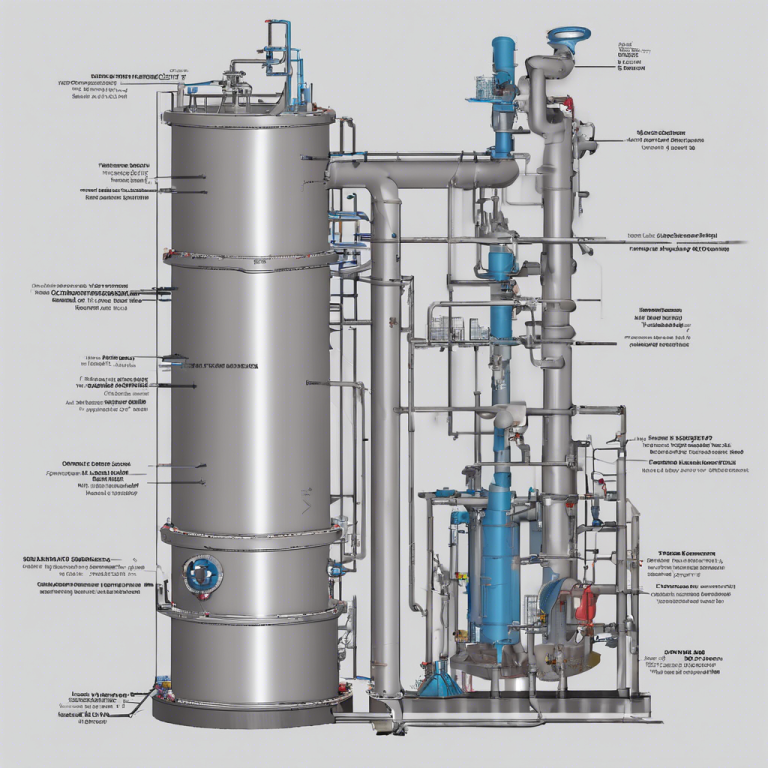

JOA has developed a broad portfolio of solutions aimed at supporting process improvement via dust, vapor, and fumes collection and extraction:

So, while process improvement may seem like a complex subject to tackle, as the above demonstrates, there are clear benefits to be had from doing so. The potential of increased productivity and minimal downtime represents real rewards for undertaking process improvement. What’s more, there is help at hand to get you started and to provide you with ongoing support.

Contact JOA today to find out more about how we can help you with a tailored solution that will optimise the efficiency of your operation.

A challenge shared is a challenge halved. Get in touch with us today and let’s see how we can work together to improve your processes and bring numerous benefits to your operation.

Product recovery

Yield Improvement in Manufacturing by Degritting & patented Deflector Hoods

It is necessary to prevent over-extraction of valuable dust and secure adequate product recovery. For effective powder restoration it is important to fully understand the motion of particles in the air that escapes from the process.

Read our whitepaper and find out how to ensure your direct product recovery.