In the over 2000 implemented systems, JOA has reduced waste-water streams, lowered pollution, improved air quality and energy efficiency for various FCMG, Pharma and Chemical manufacturers worldwide. Based on our experience, we prefer “dry” filter techniques over wet scrubbers. Also, we only apply wet scrubbers when the waste-water stream is recycled directly into the production process.

Dryer emissions in food and pharmaceutical applications have shown a great opportunity for effective energy recovery, producing steam and hot water. Other solutions are fully integrated fume exhaust systems, emission control, and air treatment systems. Read more about Energy Reduction & Recovery

How to comply with air emission limits and improve energy efficiency at the same time

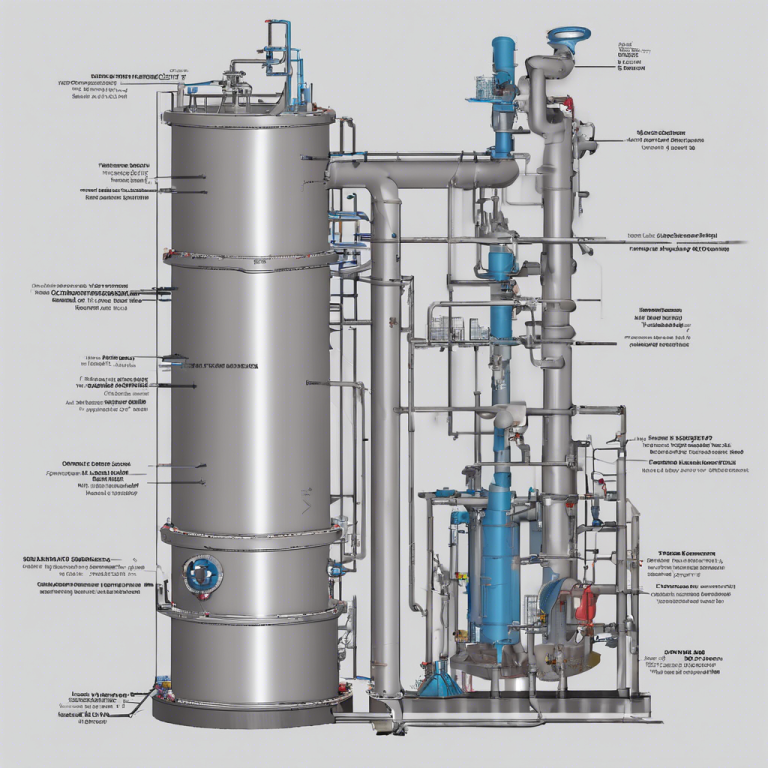

Compliance with emissions ceilings for air pollutants in the form of gases and particles is essential for your factory. A good example of provided solutions is ammonium sulphate fertilizer plants. By utilizing JOA inline-venturi scrubber effluent as process make-up water, the wet-scrubbing system, in this case, delivers both environmental and economic benefits.

JOA helps factories to comply with emission limits (like the 2010/75/EU Directive), reducing pollution, and improving energy efficiency by recovering direct energy. The exhaust air from (spray) driers and flash towers can be used to recover the energy for direct steam or hot water generation. As a result, up to 70%, energy recovery efficiency is achievable.

By utilizing JOA inline venturi scrubber effluent as process make-up water, the wet scrubbing systems deliver both environmental and economic benefits.

Martin Tukker, Operations Director

Alternative Clean Air Filtration technologies to choose from

Our Delft-based laboratories focus on providing customized industrial filtration solutions in standardized (economic) filter housings. For instance, alternative filter technologies such as Acoustic Agglomeration and photocatalytic oxidation are helping to comply with the emission limits and to provide better solutions for the FMCG, Pharma and Chemical industries by allowing effective dust and fume exhaust and emission control systems.

Fume, vapor, odor, and aerosol filters:

- Acoustic Agglomeration

- Inline Venturi Scrubbers for Vapor Elimination and Energy Efficiency

- Coalescer-belt Filters

- Photocatalytic Oxidation (also read our blog on 'Eliminating Odor Pollution')

- JOA Diamond Activated Carbon Filters

Dust Collection and UFP Filters:

- Modular Dust Filters: JDF, JRF, and Inline Venturi

- Ultra-fine Particulate Treatment Through Acoustic Agglomeration (Also read our blog on 'Effectively Removing UFP's'

- Product Recovery (ACiP) Filters and Deflector/De-gritter hoods

- Micro-climates (Local Clean Rooms) for High-end Product Protection

We are confident that our range of standardized or from scratch designed filters can meet your requirements. Our engineers and consultants are ready to get involved in designing your tailor-made air pollution control system resulting in better air quality on your site.

Filter technology

Modular filter technology

For energy recovery, the phase transition of water is an essential contributor to improved economics. JOA provides solutions for managing energy by combining advanced scrubbing technology with sustainable energy recovery.

Read more about our innovative data-based solutions by clicking below.