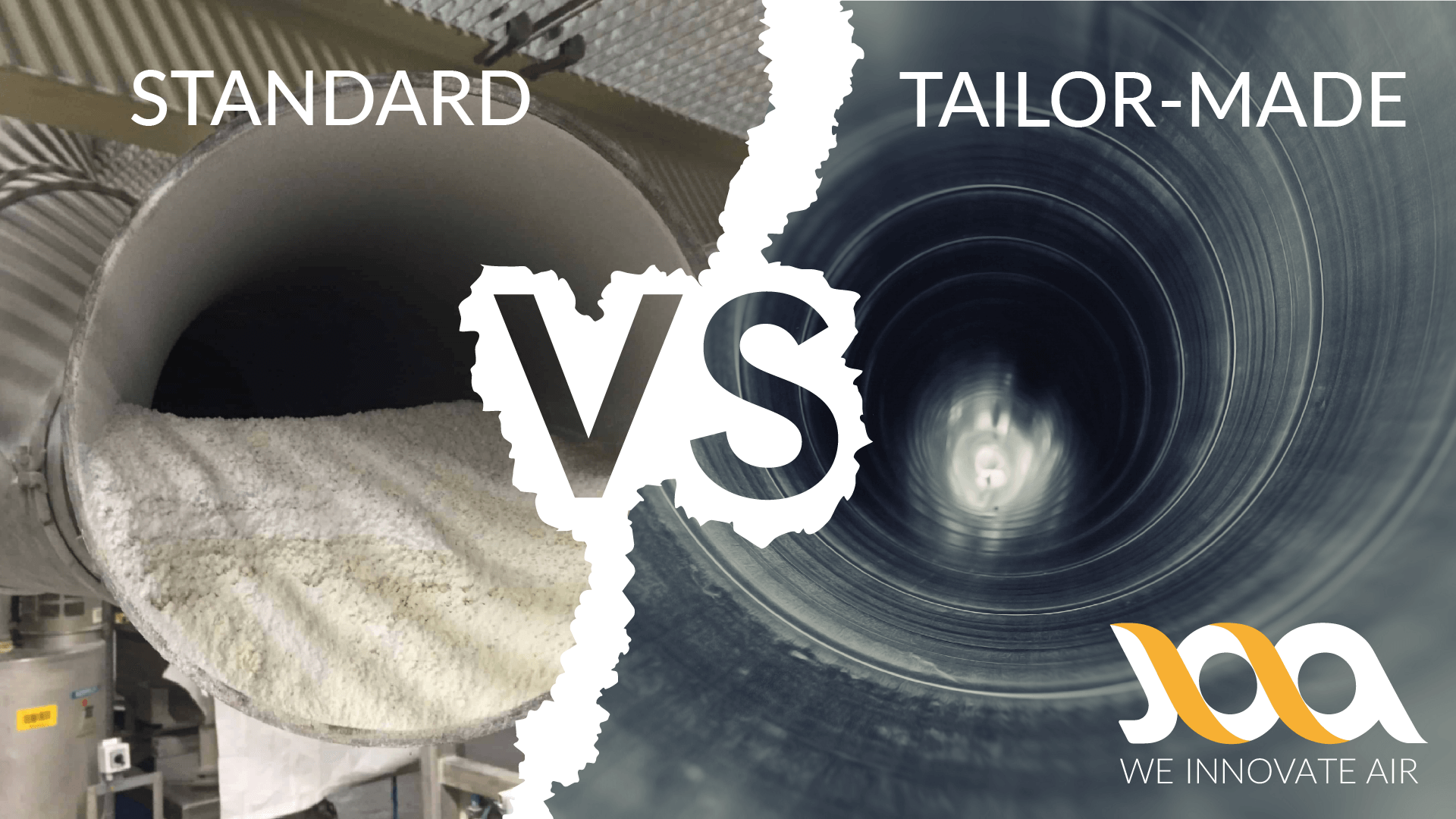

As specialists for the largest manufacturers worldwide, we believe that complex processes deserve tailor-made solutions for dust, fumes and pneumatic conveying. All our solutions are validated by Air Technical Modeling and hard data.

For over 24 years, JOA Air Solutions has been a front runner in improving processes for the largest manufacturers worldwide. We distinguish ourselves by creating emission control based on hard data and measurements, instead of ‘expert’ opinions. This way we are able to guarantee results and ROI.

Clients that trust us

We Innovate Air by:

Within the broad scope of JOA operations, we can summarize our solutions into 5 industrial challenges.

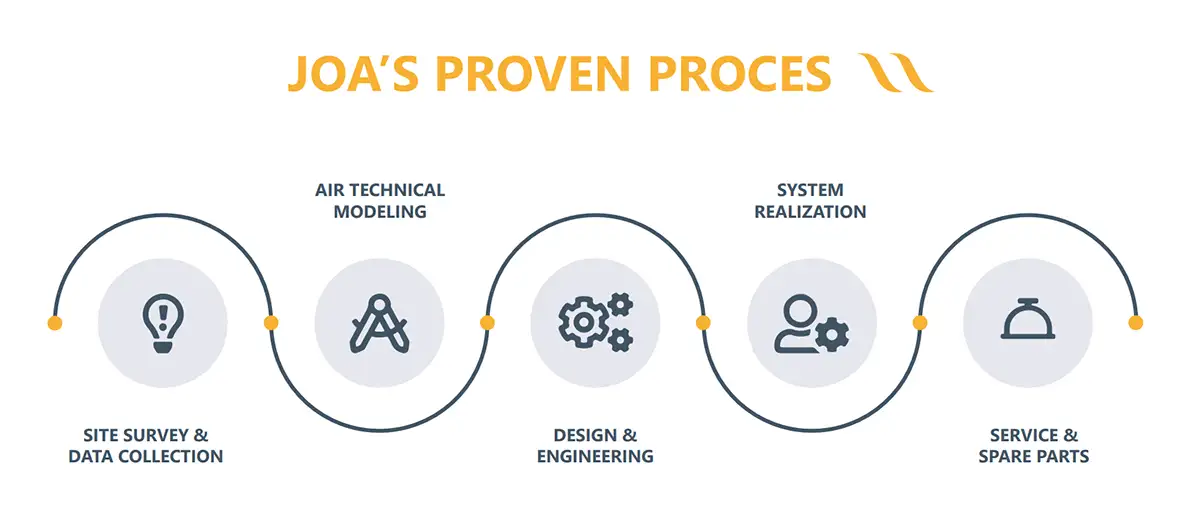

Over the years, we have developed a method to come up with a proven process that leads to the best solutions for emissions, pneumatic conveying and energy consumption.

- Site Survey & Data Collection

- Our team of engineers visit your site to fully understand your process & particles.

- Taking measurements is key to provide data for our Air Technical Modeling software

- All findings are presented in a Pre-Engineering Study

- Read more about Pre-Engineering Studies

- Air Technical Modeling

- In-house developed software

- Able to find bottlenecks in existing operations: Air Flows, Extraction Capacities, Optimal Duct Routings

- Validates and guarantees future outcomes of our designs

- Read more Air Technical Modeling

- Design & Engineering

- Based on the collected data, our design team starts designing

- Integration of proven designs and OEM Materials

- Future proof: Ready for upgrades in case of changing legislation

- Read more about Design & Engineering

- System Realization

- Building all systems in the Netherlands to guarantee quality and plug and play implementation

- Clear planning in advance offering room for flexibility

- Commissioning by our experienced Project Managers, able to overcome unexpected challenges and enabling 1st time right implementations.

- Read more about System Realization

- Service & Spare Parts

- After System Realization, we like to stay in touch to assist with preventive/corrective maintenance, spare parts and future updates.

- Read more about Service & Spare Parts

Why choose JOA Air Solutions?

- Conducted over 200 Pre-Engineering Studies leading to Predictive Modeling, Process Guarantees and first-time right Implementation

- Over 1000 custom-made Extraction Systems implemented for both greenfield and brownfield sites

- Reliable and specialized partner, trusted by the largest manufacturers, worldwide

- Multidisciplinary team of in-house engineers and designers that ensure fully aligned and co-created systems

- Experience from various industries ensure out-of-the-box solutions for your specific requirements

- Our in-house R&D department makes sure we remain leading in cutting-edge Industrial Air Filter technology

- Our track record shows that our Air Filtration Systems maintain their value and are flexible enough to accommodate future growth and upgrades

We keep our promises about emission control

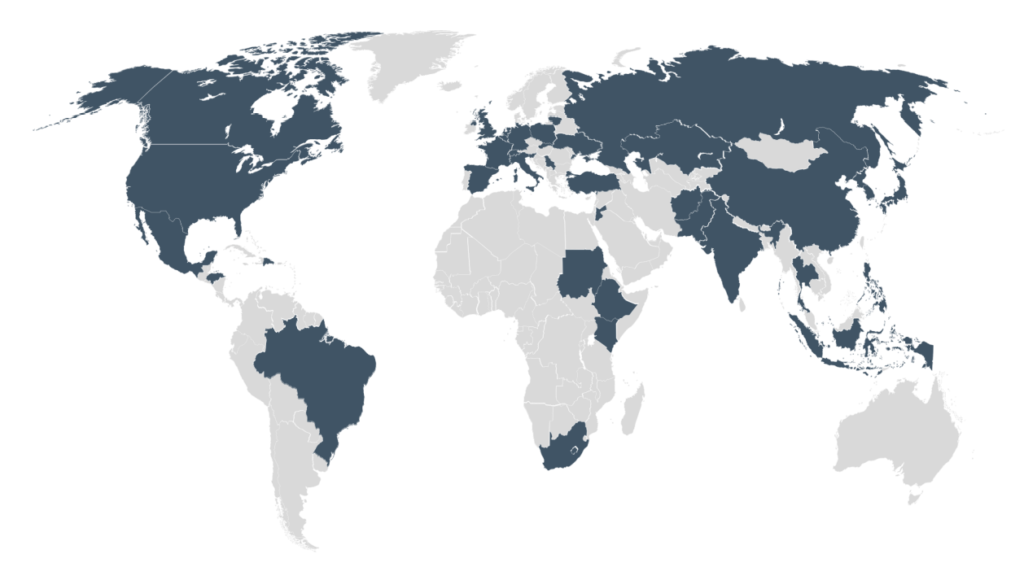

Reliability is one of JOA's core values. We start every project with advanced modeling to take inventory of the options and minimize risks. Thanks to our regional offices and partnerships, we are able to provide direct support to our customers around the globe.

Since JOA was established, we have grown into an international organization with our headquarters and R&D facilities located in The Netherlands, close to the renowned Technical University of Delft. The international culture of our company is reflected by our team of engineers and the fact that 60-70% of our air cleaning systems are installed outside of the Netherlands.

JOA has many partnerships with various partners. All partners contribute to providing better solutions for our clients. Some examples are the ‘Royal Dutch Metal Union’, Viridi Air and the Netherlands Organization for Applied Scientific Research (TNO).

As JOA Air Solutions has a strong commitment to contribute to prevent, reduce and deal with harmful industrial emissions, we are a partner of Viridi Air. This means that for every new client or system implemented, a specially selected tree will be planted. JOA is admitted to become a partner due to its demonstrable contribution to emission control worldwide.

Viridi Air plants air purifying trees that absorb polluted gaseous and solid particles like fine dust, NOx, Ammonia, Ozone and CO2. With this scientifically proven filtration technique, we support clean air and increase biodiversity at the same time.

Proven air technology, balanced with groundbreaking technical innovations

JOA provides emission control through dust and vapor extraction systems, as well as air-quality and energy-recovery solutions in a wide range of industrial settings. Our proven technology is based on our history as a leading air filtration system manufacturer. We developed and implemented bespoke Dust & Fume Extraction Systems, often exceeding expectations.

JOA makes a difference by:

-

JOA proprietary predictive technical modeling tools and workflows to minimize project risk prior to installation. Due to our simulations, JOA systems start working immediately and come with process and air-quality guarantees enabling peace of mind and uptime for your site.

-

JOA technical innovations around emission control have helped increase Air Quality for both Greenfield and Brownfield sites. A wide track record of projects include applying Acoustic Agglomeration techniques for ultra-fine dust removal, often also improving noise levels and photocatalytic oxidation for the elimination of vapor.

-

Sharing knowledge through Consultancy Studies resulting in tailor-made Concept Designs.

-

On-time implementation and commissioning by our dedicated team of multidisciplinary Project Managers. Read more about Realization

It is our common passion to apply air innovations for better quality of life, processes and work.

Martin Tukker, Operations Director

It has become more and more evident that ultra-fine particulates and aerosols have a direct, harmful effect on our health and need to be removed. Also, our project managers and engineering teams are attuned to the current economic developments and direction of your industry. This awareness has made JOA into the solution-driven company that it is today.

JOA is able to compete in international markets, minimizing production costs through the direct integration of our 3D engineering and our automated production machines. JOA is a leading technology provider for air recirculation systems and energy-recovery in “green” factories.

To deliver an integrated, ergonomic customized solution to you, it is essential that your process, engineering, and production teams engage closely with our specialists and consultants. We strive for successful cooperation that provides our customers with pragmatic solutions and punctual project realization. We will not rest before all systems run smoothly and advise on preventive maintenance, possible upgrades and spare parts.

Our technology provides a healthy and safe work environment with efficient usage of base materials, resources, and energy, enabling you to realize your goals.

Bas van den Bogerd, Business Development Director

Values of JOA Air Solutions

- Reliable, Trustworthy and Client focused partner for complex Dust, Vapor and Aerosol Challenges

- Improving Indoor Air Quality to reduce Operator Exposure and increase Safety

- Turnkey installation and commissioning increasing uptime and peace of mind

- Systems built in The Netherlands according to the highest industry standards

- Complex processes need to be adjusted to your specific industrial environment and requirements to be able to create balanced and energy efficient systems

- Reduce risks by preventive GCM Modeling

- Dedicated to help realize your Sustainable and Compliancy Goals