After project completion, we like to stay in touch and offer you the best possible service. JOA’s servicing and monitoring have an interactive and personal approach. Both existing as our own systems can be serviced, provided with spare parts of adjusted to fulfill your future needs and requirements.

Preventive Maintenance reducing costs and downtime

JOA monitoring and modeling services is an interactive approach providing adequate preventive maintenance advice, realizing long term reliability of your JOA exhaust air treatment installations and feeding system.

Recommended spare parts to maintain uptime

Based on technical experience and on-site survey of the current running projects, an overview spare part list will be provided to prevent system failures or worn components. Thus, we ensure the smooth operation of instruments and increase productivity.

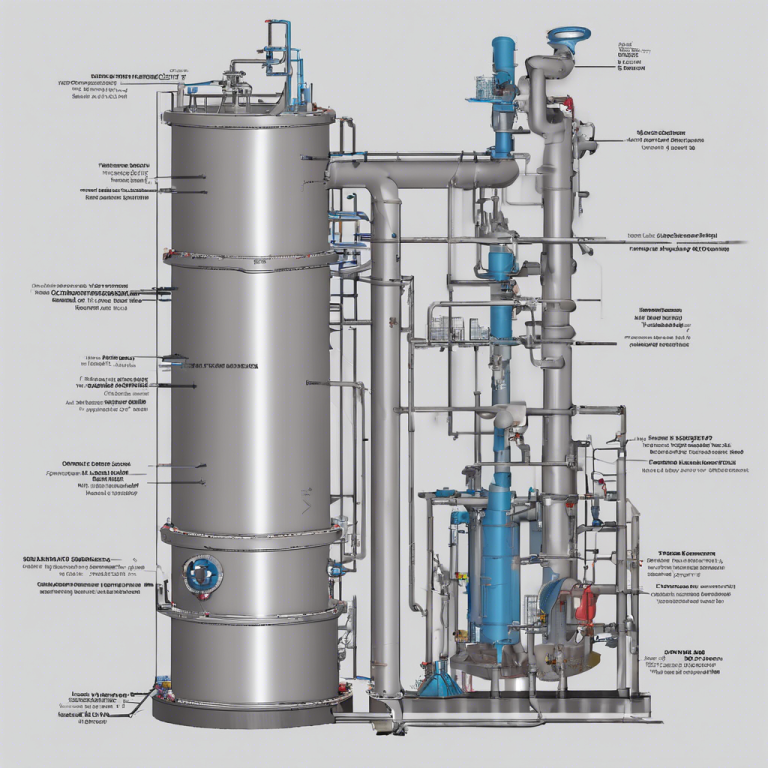

Upgrading existing Filtration Systems

For existing systems precise modelling (history matched GCM) delivers the following improvements:

-

Prevention of condensation related fouling (placement of make-up air units)

-

Precisely balanced, controlled and stable extraction systems (stable operations of key production equipment)

-

Overall risk reduction, knowing the system will work (as over 1000 modeled systems have been built already)

-

Predictive modeling provides a meaningful process guarantees

-

Upgrade equipment to meet ATEX requirements and deliver a safe working environment