Paints & Coatings

The side effects of manufacturing in the Paint & Coatings industry, often entails the production of Toxic Waste, emissions, air pollution, CO2, Volatile Organic Compounds (VOC’s) and Noise Pollution. JOA Air Solutions is an expert is finding solutions and improving processes for Paint & Coatings manufacturers in the fields of Emission Control, Filtration, Explosion Safety, Healthy Work Environments, Energy Reduction & Recovery and Emission Limits & Legislation.

Handling Emissions effectively in the Paint & Coatings Industry

The manufacturing of Paint and Coatings, may include:

| Chemicals | Latex |

| Coatings for the Automotive Industry | Pigment (powder) |

| Dyes | Powder Coating |

| Fillers | Surface Coatings |

| Inks | Toner and ink |

| Laminates | UV protection |

| Wet Paint |

While manufacturing the products above, your operators health & safety is at stake. Harmful pollutants emitted when producing Paint or Coatings:

| Cadmium | Solvents |

| Hexavalent Chromium | Silicones |

| Phosphates | Vinyl |

| Pigments | Volatile Organic Compounds (VOC’s) |

| Polycyclic Aromatic Hydrocarbons (PAH) | Exhaust Gases |

| Polyester | Zinc Oxide |

| Polyurethane | |

How to create effective filtration of Paint & Coating Emissions

Your operations rely on steady performance, reliability and efficiency. A high quality filtration of air, dust and vapors is crucial to keep your work environment clean and healthy, reduce explosion risks and maintain your equipment in the best possible condition. To achieve your goals, we propose the following plan.

-

Data Collection & Measurements

We believe, no good decision can be made without data. It might be tempting to choose a ‘quick and dirty’ standardized solution. On the long run, truly understanding your site’s specific requirements is the foundation of Operator Health, Explosion Safety, Maintenance reduction and Energy Savings.

-

Consultancy & Design based on Modeling

Only data has no value. With our in-house developed Air Technical Modeling Software, we are able to truly understand your site’s operations and bottlenecks. Our Design Engineers have experience in finding the best solutions and improvements for the largest and most complex Chemical production sites worldwide.

-

Building & Implementation

No system is manufactured, before a thorough investigation and understanding of your product and process. Our wide portfolio of extraction and emission control equipment builds on a large database of patents and proven designs. In occasion, our R&D department stands ready to find innovative solutions and co-create new equipment.

With this approach, you can rely on our expertise to achieve:

-

VOC Emission Control

-

Compliance with Environmental Regulations

-

Healthy & Safe Work Environments

-

Process Improvements, increasing efficiency, lower operational costs and energy reduction or recovery

-

Extraction of Pigment Dust carrying dangerous toxic metals

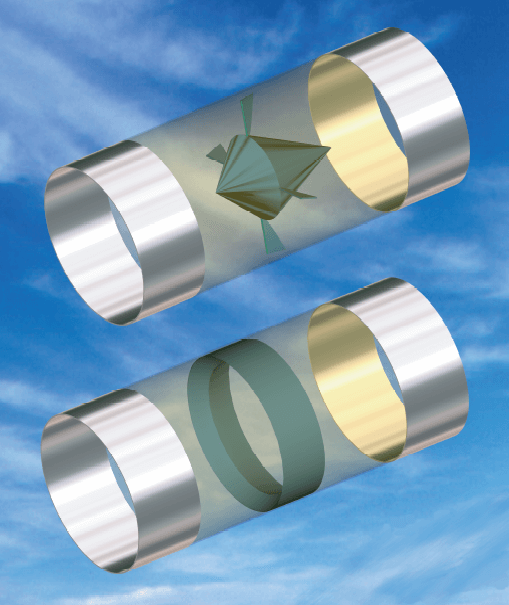

Industrial Solutions for the Paints & Coatings Industry

To maximize efficiency at large-scale production, JOA offers a wide variety of equipment that will be tailored to your specific site and process. All extraction systems are validated by Air Technical Modeling to guarantee future performance and ROI.

Related Topics, Solutions and Products

Every industrial challenge is unique. Contact JOA to share your thoughts on where you would like to improve your process

We are always there to discuss your challenges. Our goal is to guide you on your path to high performance operations and Healthy & Safe environments.

Share your Challenge with us