Based upon the Pre-engineering Study, including conversations with our client, a preliminary engineering design will be provided. Our team of in-house engineers and R&D Department team up together with the client to effectively create solutions immediately in 3D.

Lean 6Sigma-based project execution method to guarantee:

-

Effective project definition phase

-

Accurate shop survey

-

Measurement program providing adequate data to define before and after states

-

Viable 3D Concept Design

-

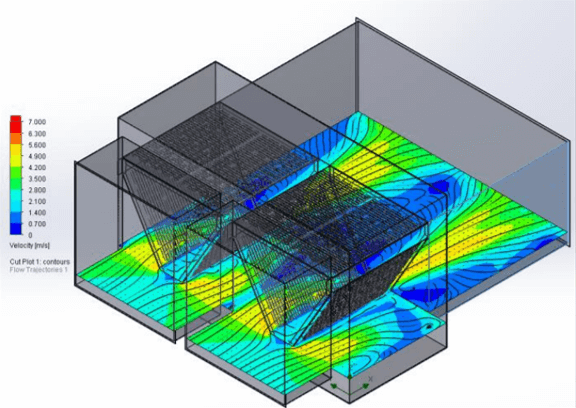

Know how your system performs on your site before its built

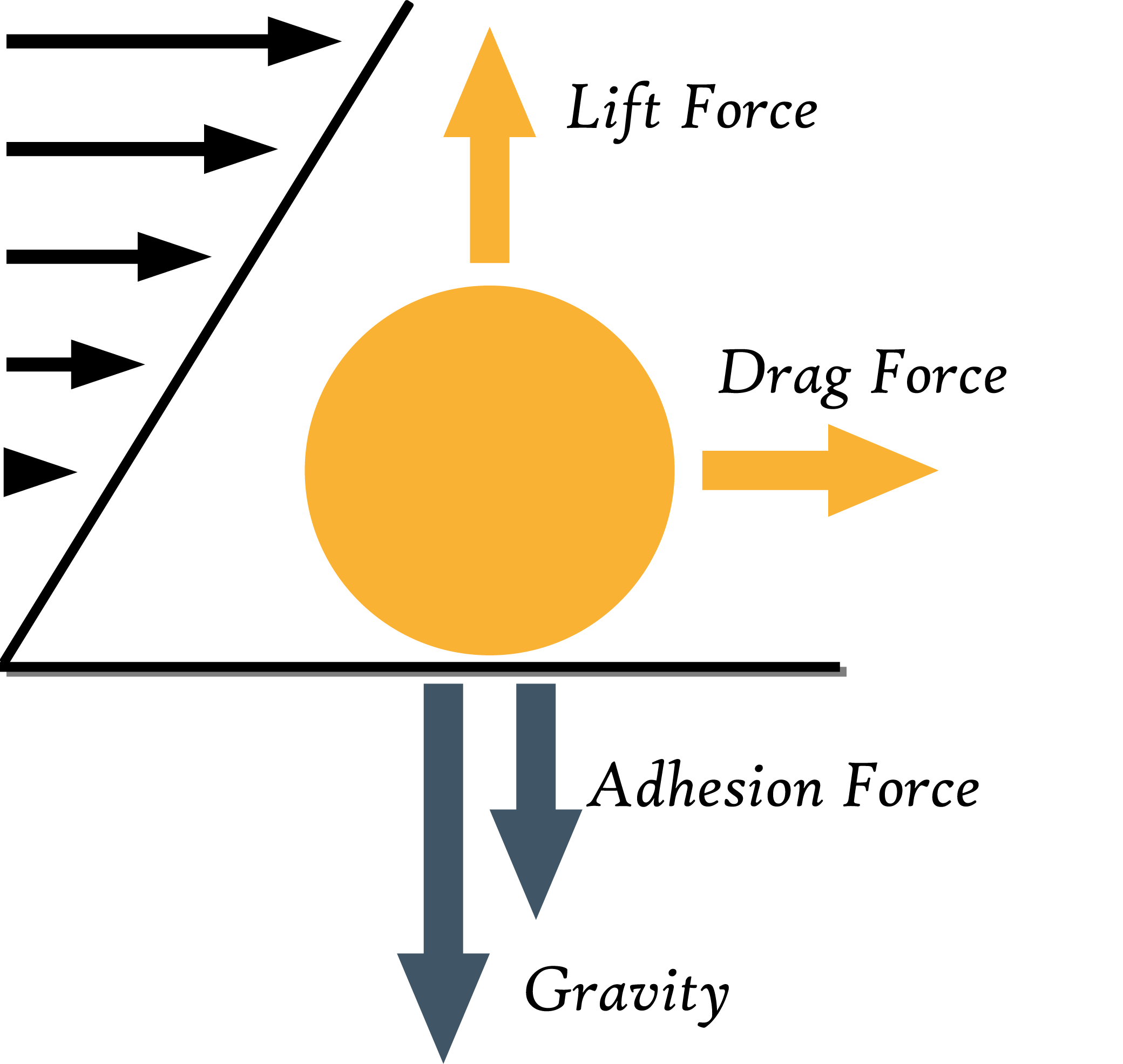

Understanding the interaction of particles in an Air Flow

There are four forces working on a particle

-

Adhesion

Relatively strong force for small particles. However, it can vary widely (orders of magnitude) due to relative humidity, kind of material, and processing history. Adhesion keeps particles attached to a surface.

-

Gravity

The easiest force to calculate once the particle density is known. It is a straightforward measurement and calculation and can keeps particles attached to a surface.

-

Lift and Drag

These are both directly related to the average flow velocity and size of the particle. Both Lift and Drag try to remove particles from the surface. There are many different models with various coefficients that depend on the flow regime (laminar, turbulent, transition) for the lift and drag coefficients.

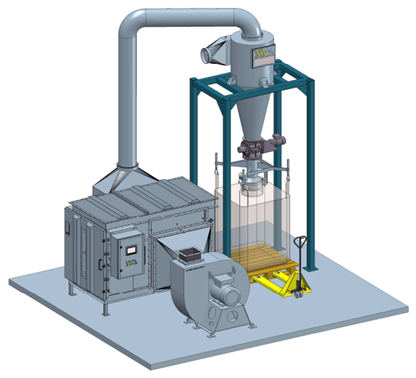

Engineering for New Systems

For new systems and greenfield sites, JOA’s team of in-house engineers provides:

-

Prevention of condensation related fouling (placement of make-up air units)

-

Precisely balanced, controlled and stable extraction systems (stable operations of key production equipment)

-

Overall risk reduction, knowing the system will work

-

Predictive modeling provides a meaningful process guarantee

-

Minimal fouling

-

Optimized energy usage/reduced make-up air requirements

-

Extract on demand (carrousel)

-

Absolute balancing (stable operations)

-

Minimized product loss (only slight negative pressure to prevent over extraction)