Clients that trust us with:

Data Driven and Reliable Solutions

Wasting resources should be reduced to a minimum. Assets and operators deserve a healthy and safe work environment compliant to all emission legislations.

Recognize any of these Challenges on your site?

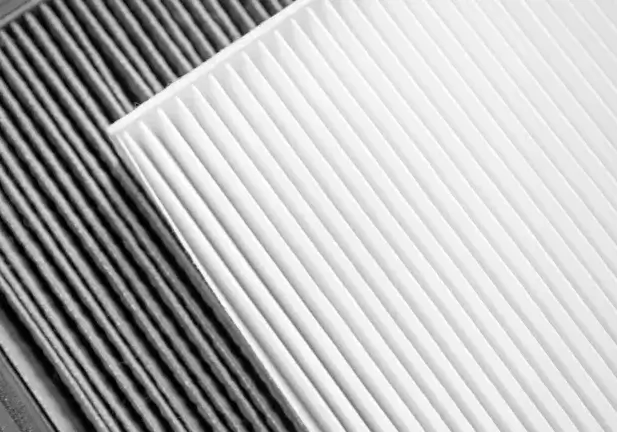

Dusty Workplaces

Cross Contamination

Over-/Under-extraction

Wasting resources & Energy

No Clear Insights/Control

High Maintenance Costs

Losing license to Operate

Uncertainty of downtime

Health hazards

Environmental footprint

Emission Limits & Compliance

Fear of fire and explosions

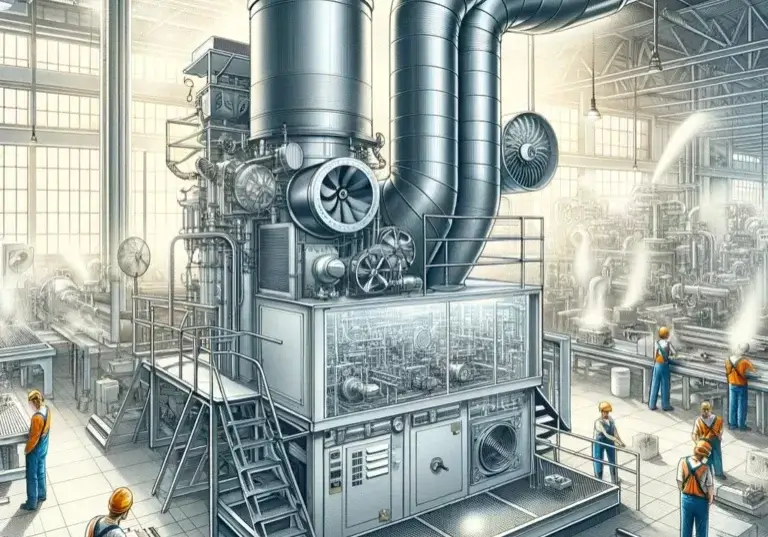

Start Improving your site's processes

JOA Air Solutions provides tailor-made, turnkey and guaranteed improvements to all your Dust, Vapor and Aerosol challenges. With JOA you will reduce downtime, improve OPEX and become more safe & sustainable. By effectively predicting your required specifications in advance, we implement reliable 1st-time-right Industrial Emission Control.

Sharing your challenges with JOA leads to:

Emission Control & Process Improvements realized for

manufacturers in the following industries:

Healthy Work Environment

Keep your operators healthy and reduce diseases with efficient extraction systems.

Energy Reduction & Recovery

Realize both environmental as economic benefits. Don’t let any heat go to waste.

Process Improvement

Tailor-made, balanced and downtime reducing extraction systems will outperform standardized solutions every day.

Start Improving your Process

Stop wasting resources by unbalanced and inefficient extractions sytems. Learn more in this Whitepaper about Energy Reduction & Recovery.