Pharmaceuticals

The side effects of manufacturing in the Pharmaceutical and Biotech industry, often entails complying with sturdy health & safety requirements while meeting quality standards. The production in cleanroom environments needs to allow the flexibility of batch changes, while preventing cross-contamination or higher operational costs. JOA Air Solutions is an expert is finding solutions and improving processes for Pharmaceutical manufacturers in the fields of Emission Control, Filtration, Explosion Safety, Healthy Work Environments, Energy Reduction & Recovery and Emission Limits & Legislation.

Handling Emissions effectively in the Pharmaceutical Industry

Processes in the Pharmaceutical or Biotech industries often include:

| Capsule Filling | Oral Sold Dosage (OSD) |

| Cosmetic Products | Pelletizing & Spheronization |

| Drugs | Pharmaceutical Ingredients (HPAPI’s) |

| Drying Processes | Polyols |

| Fluidized Bed Processes | Powder Batch Mixing and Milling |

| Granulation (Dry / Wet) | Statins |

| Lab testing | Surface Coating |

| Medicines | Tablet Pressing |

| Mixing, Dosing and Weighing | Tube Feeding |

| Oncology Treatments, like Highpotency Compounds | Vitamins |

| Packaging | Weighing & Packaging |

Manufacturing these kind of solids and powdered drugs are often accompanied by quite some dust related issues that may be hazardous, toxic or combustible. It’s our responsibility to reduce the risks for operators and be compliant with regulations. Also, cross-contamination and over-extraction should be prevented to improve efficiency and quality.

How to create effective filtration of Emissions during Drug Production

Your operations rely on steady performance, reliability and efficiency. A high quality filtration of air, dust and vapors is crucial to keep your work environment clean and healthy, reduce explosion risks and maintain your equipment in the best possible condition. To achieve your goals, we propose the following plan.

-

Data Collection & Measurements

We believe, no good decision can be made without data. It might be tempting to choose a ‘quick and dirty’ standardized solution. On the long run, truly understanding your site’s specific requirements is the foundation of Operator Health, Explosion Safety, Maintenance reduction and Energy Savings.

-

Consultancy & Design based on Modeling

Only data has no value. With our in-house developed Air Technical Modeling Software, we are able to truly understand your site’s operations and bottlenecks. Our Design Engineers have experience in finding the best solutions and improvements for the largest and most complex Chemical production sites worldwide.

-

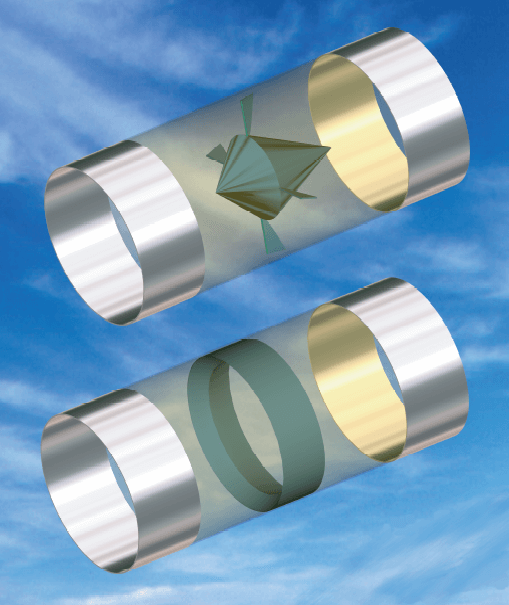

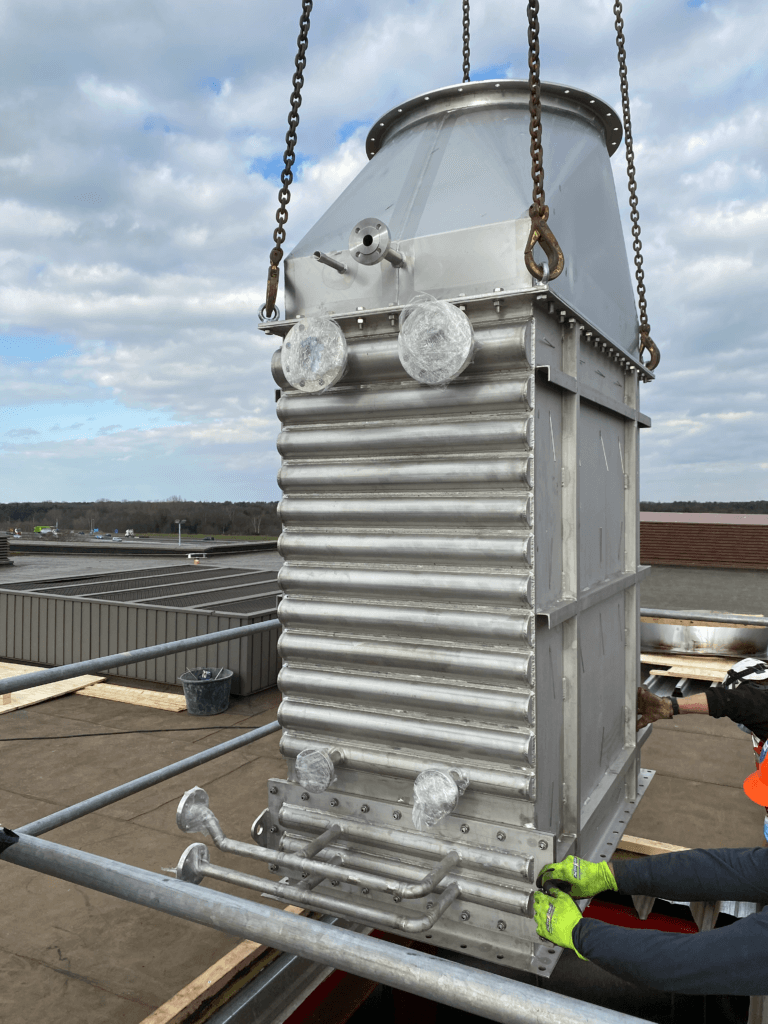

Building & Implementation

No system is manufactured, before a thorough investigation and understanding of your product and process. Our wide portfolio of extraction and emission control equipment builds on a large database of patents and proven designs. In occasion, our R&D department stands ready to find innovative solutions and co-create new equipment.

This approach gives you control over your sensitive production process. Benefits of working with JOA includes:

-

Prevent employees from being exposed to potent compounds and ensuring a higher comfort level and work satisfaction

-

Minimize product or batch rejects, liability and quality defects

-

Preventing contamination and cross-contamination

-

Compliance with environmental and workplace regulations and legislation

-

Minimized costs and maintenance due to efficient filtration

-

Long lifespan of Filters, Fans and related equipment due to balanced process

Considerations when selecting Dust Collection Solutions for the Pharmaceutical Industry

When designing new or upgrading existing equipment, the following factors are taken into account:

- Particle Characteristics

- Human Health Hazards

- How much dust is produced? What are the velocities

- What is the moisture levels

- Is the dust combustible? What dust explosion risks are present

- Does the process include dangerous chemical vapors, gases or Volatile Organic Compounds (VOC’s)?

Consistent and accurate operations are a key priority. With tailored industrial solutions from JOA, you will optimize your performance.

Industrial Solutions for the Pharmaceutical & Biotech Industry

The process of manufacturing drugs frequently includes operations like powder feeding, powder blending, milling, granulation of very fine powders, coating and tablet pressing. With multiple batches being produced, cross contamination needs to be prevented at all cost. A clean environment is essential to maintain compliant to the highest standards of GMP.

Every industrial challenge is unique. Contact JOA to share your thoughts on where you would like to improve your process

We are always there to discuss your challenges. Our goal is to guide you on your path to high performance operations and Healthy & Safe environments.

Share your Challenge with us