How to make a future proof manufacturing plant?

Currently, legislation surrounding the control of hazardous substances and industrial emissions is extremely dynamic. A growing understanding of the environmental impact of such substances, combined with governmental requirements to meet ambitious climate targets, ensures the emergence of increasingly stringent regulations – all around the world.

Generally speaking, legislation attempts to consider four main jurisdictions and their impact on the environment, the health of people and the safety of manufacturing processes:

- Carcinogens

- Toxic substances

- Bioaccumulates

- Hormones

Such regulations are positive in both intent and in their effect upon health and the environment. However, they do pose a number of challenges to a manufacturing sector, for which it is no longer sufficient to ‘just’ be compliant in terms of industrial emissions.

Having selected an effective industrial air filtration system, today’s manufacturer – like their filtration system – needs to follow best practice, remain up-to-date and versatile in the face of changing rules in order to become future-proof.

Already many companies are adapting to these changes and looking to prepare for tomorrow’s world. As well as challenges, there are also benefits in doing so; energy efficiency in operations can offer a tangible return on investment.

Plus, with the topical nature of environmental issues and prevalence of subjects such as the United Nations Sustainable Development Goals, such practice is also an opportunity for the forward-thinking business to demonstrate its social responsibility.

Challenges to overcome: Considering specific requirements of your operation

There are numerous standardized industrial filtration systems on the market. On initial consideration these can seem very appealing. After all, they represent a fast solution and, being produced in series, often carry what seems like an attractive price tag.

However, it is worth bearing in mind that all operations are different and, therefore, vary in their requirements.

Tailoring a system for long filter life

A standard filtration system is likely to fulfil these requirements – for a time. In the end, however, the specific requirements of the system are liable to require more – or less – of a filter than it has been prepared for.

As a result, maintenance requirements are likely to increase considerably and filter lifespans may be all too short.

Choosing for a scrubber or a filter?

Additionally, applying a filtration system without in-depth consideration of the specific requirements of the operation, could lead to the incorrect solution being used.

Efficiency under threat

Standardization also threatens the efficiency of a filtration system. It is not unheard of for a manufacturer to employ multiple, standard, local filtration systems. There is logic behind this; decentralized systems offer a means for filtration to continue in the event that one system (temporarily) ceases working. However, in many cases, a small number of centralized units with all pipework connected would be of greater efficiency.

Particularly in the face of change – for example from next generation legislation – it is harder to upgrade a standard solution than one that has been tailored for the unique qualities of an operation.

Upgrading existing filtration systems

As new legislation brings with it the potential requirement for increased filtration capacity, it is important to consider the capabilities of an existing system.

Increasing capacity

Unless a standardized solution has been used (see above), it is highly likely that the system will have been designed with a specific capacity in mind. If this capacity is required to increase, it is possible the system will need to be upgraded.

Suddenly, filters are being called upon to handle higher loads and greater air velocities than those for which they have been developed.

Safety & compliance

In addition to threatening the system’s ability to comply with regulations, handling greater loads can have implications for safety – for example, increasing the risk of explosion. Undertaking a tailored upgrade provides an opportunity to ensure that all components contain the relevant, up-to-date safety features as required by the increased capacity.

Maximizing uptime

For a system to be compliant, it is of course critical that it is operational. Downtime for the system is liable to equal downtime in production. This means having the right system in place for the specific requirements, so that it can do what is needed of it without requiring regular repairs, unforeseen maintenance or excessive filter replacement.

In the event of a system failure, the desire for optimal uptime can make a quick fix solution seem attractive. However, a fast repair solution, as with a quickly executed upgrade, may compromise both compliance and safety.

The system should be well maintained in order to protects its capabilities and maximize uptime. I t is important that any damage is professionally repaired at the earliest opportunity.

Future-proofing with industrial best practices: Going straight to the source

There are a number of steps that can be taken to ensure maintained compliance in the face of changing legislation:

- Source elimination

- Process improvement

- Source Extraction

- Dilution

Eliminating emissions at the source

Elimination of emissions at source is a straightforward way to maintain compliance. It is also something that can be managed in-house. We can also support and assist with CFD calculations, Shop Surveys and process improvement suggestions. We often also measure before and after situations with data logging:

- Temperature

- Humidity

- Air Flow Patterns

- VOC’s

Reducing impact with process improvement

Another step that can be managed in-house is changes in the process in order to reduce their potential for negative impact in line with (future) regulatory requirements. For example, If the manufacturing process requires addition of a liquid or powder, consider whether the unloading or filing process can be carried out more slowly and in stages.

Increasing control with balanced Source Extraction

The benefits of more controlled product flow throughout the process are manifold; it reduces emissions at source and also, as a neater operation, makes the extraction of potentially offending substances far easier. Such control allows product recovery because, often in these situations, a more gentle process results in less emissions through venting opening and extraction of valuable product.

Care take at the outset may suggest a less time-efficient operation, though in the vast majority of cases, the process allows for it; a container or bucket takes time to empty and can be carefully topped up at regular intervals to avoid disrupting the process.

When extraction is still not optimized accordingly, hoods can be adjusted or designed tailor-made to specific requirements.

Avoid mixing substances

Avoiding the mixture of substances prevents valuable product and raw materials being extracted to a central filtration system. If expensive raw material is extracted then it is best to remove it from the air stream prior to its being mixed in the central waste bin.

This can be done by installing a cyclone just after the extraction point in order to recollect the valuable material for reuse.

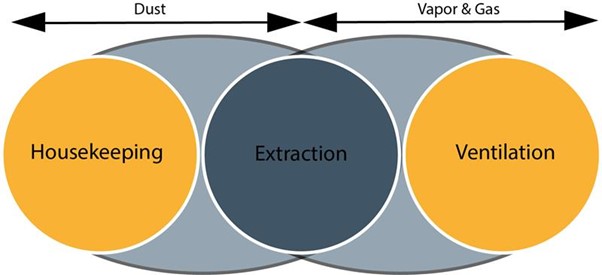

Dilution & Housekeeping as solution after source extraction

After source elimination, creating process improvements, and extraction at the source with emission control systems, the final solution direction is dilution. Dilution is the process of decreasing the concentration of dust or vapor in the air. This can be done mainly by ventilation or air treatment.

Predictive dilution scenarios help produce insights in the most economical ways to meet MAC-values and future upgradability.

When diluting harmful gasses or vapors is still needed after source elimination and extraction, it can have a positive impact on the indoor environment. A balanced system includes a holistic view of all requirements on a healthy work environment, safety and compliance.

Even with the best extraction in dusty environments, good housekeeping is the way to go. Central vacuum cleaning (CVC) systems have an important role in keeping production areas dust free and potentially explosion safe.

Learn more about source elimination, extraction and dilution: Webinar: Improve Vapor & Fumes Emission Control

Product recovery via prevention of over-extraction

As important as it is to ensure a healthy working environment, it is also important to do so in a manner preventing over-extraction of valuable dust and to secure adequate product recovery.

The extraction system should be finely balanced, preventing too much negative pressure at extraction points to avoid unwanted extraction.

A successful system may feature a fluid dynamics-based design considering particulate behavior and air speed. It should facilitate elimination of airborne dust, while recovering up to 45% of product.

The design for such a system will take into consideration a number of factors:

- Motion of particles that ‘escape’ from the process

- Knowledge of particle settling velocity

- Knowledge of velocity relaxation

- Understanding of particle to particle reaction

There are a number of ways in which in particles can be removed from the air stream in order for recovery to take place:

- Cyclone Separators

- Scrubbers (see End-of-pipe solutions)

- Impactors

- Deflection & Degritting

- Filters in combination with Acoustic Cleaning in Place

Cyclones separators

Mainly used with heavier dust particles, like raw materials. They work much like a centrifuge, but with a continuous feed of dirty air. The inside of a cyclone chamber creates a spiral vortex, similar to a tornado. Cyclone filters have a low particle efficiency result.

Impaction

The impactor model is particularly interesting. In the standard impactor model, the flow direction is changed abruptly. Any particle unable to make the sharp bend resulting from this will hit an impaction plate.

A variation of this theme is the virtual impactor whereby a small air stream contains particles that are unable to make the same bend as the air flow takes.

Deflection and Degritting

The process can apply either a deflector or a degritter hood. The deflector is a virtual impactor for finished product or fine powder. It collects only airborne particles. Only particles able to pass a small slit are lost. The remainder fall back in such a way that product recovery is maximized and pressure drops minimized.

The degritter hood works in a similar manner and also features a virtual impactor. By selecting the air velocity and gap width it is possible to set a cut off point for the particle diameter that can be recovered. Particles unable to follow the air flow are collected and fall back onto a conveyor belt.

Other degritter applications include pre-separation of large dust fractions to reduce filter loading for long-term filter performance. By tuning the gap width and air velocity, it is possible to set a cut off point for the particle diameter.

Filters in combination with Acoustic cleaning in place

Another interesting product recovery method relates to pneumatic conveying filters. Acoustic Cleaning in Place (CiP) uses acoustic agglomeration to recover ultra-fine powder from filters. It not only offers a high level of product recovery, it prevents cross contamination after batch changes.

Read more about Acoustic CiP here

End of pipe solutions

A range of solutions for handling emissions are certainly available at the end of pipe. These include the following:

- Filtration

- Oxidation

- Scrubbers

- Acoustic agglomeration

- Heat recovery

Filtration

There are numerous types of filtration system available – envelope filters, bag filters, pleated filters, etc. The type and size selected is based upon the type of dust handled and required system capacity .

In selecting a filter, safety is also of paramount importance. In many cases, dust is explosive. It is, in these cases, of extreme importance that the filter contain ATEX Directive explosion safe equipment. This, including components such as rotary valves, ATEX compliant instrumentation, chemical explosion suppression systems and sprinkler systems, ensures that the explosion is prevented from reaching either the source or end point of the system, containing damage and minimizing downtime.

Oxidation

This process uses a Regenerative Thermal Oxidizer (RTO) to burn off vapors. However, this method is not without its drawbacks. In many cases oxidation is supported by burning gas. This equals a significant increase in CO2 emissions, which is often contrary to the intention of new and upcoming regulations.

There are electrical solutions available, which produce less emissions, however these also feature high energy consumption.

Scrubbers

With an industrial scrubber, air is cleaned by recirculating water. Atomized scrubber water provides droplets, on which particles impact. The particle containing droplets then pass into a droplet separator. Here, the droplets are separated from the air stream. At the top of the separator, the cleaned air is conveyed to a fan.

The fan will have its own cleaning loop, controlled by an automatic pneumatic valve. The dP pressure inside the scrubber is checked by pressure transmitters at the inlet and outlet to ensure the condition of the process is good.

After the fan, the air goes to a silencer and is released via the stack.

Acoustic agglomeration

This solution uses high frequency sound waves to make fine airborne particles collect and form into larger agglomerations, thus enhancing the technology of the traditional dust filter.

Read more about Acoustic Agglomeration here.

Heat recovery

An interesting solution in the face of increasingly stringent environmental legislation, heat recovery provides the opportunity to re-use heat generated during the manufacturing process. For example, this can be used to heat the manufacturing plant, reducing the demand on energy from other sources or to generate warm cleaning water and steam.

Heat recovery combines the benefits of a more environmentally conscious operation with increased (cost) efficiency by using heat exchangers.

JOA: Identifying your specific filtration requirements

In order to establish exactly what the specific requirements are for your industrial filtration system – and what steps to take in order to ensure its continued suitability for future use, it is advisable to consult a dedicated professional.

JOA is a specialist in the design and installation of industrial filtration systems with over two decades of experience. This track record positions the company’s engineers well to provide advice and solutions to keep an operation up-to-date and compliant, even as rules and regulations continue to change.

Download Industrial Air Filtration Checklist

Combining proven solutions with innovation

Over the years, the company has developed a range of proven solutions. It builds on these as a foundation to provide an entirely tailored solution, every time, in the understanding that no two industrial air filtration systems are fulfilling the same requirements.

For each occasion, the company creates a solution based on its tried, tested and proven method:

- Consultancy:

- On-site Inspections

- Measurements

- Operator interviews

- Reporting findings & recommendations

- Air Technical Modelling:

- Maintaining optimum conveying velocities

- Selecting the right duct diameters

- System Balancing

- Engineering an optimized system

- Evaluation of current de-dusting/vapor extraction effectiveness

- Design compliant to legislation (ATEX, emission limits, etc.)

- Creating tailor-made systems or implementing proven systems, like patented hoods

- Realization

- Planning & Preparations

- Implementation, working with our own trusted partners or your local suppliers

- Commissioning

- Service

- Maintaining extraction quality

- Spare parts recommendations

- Operator training on preventive maintenance

- Planned Maintenance, often carried out during a production stop

Based on the detailed analysis that JOA performs, it is able to recommend the most appropriate solution for the unique specifications of each individual manufacturing operation it encounters.

Benefits of having an optimized Air Filtration system implemented:

- Reduction of cleaning time and reduced downtime

- Reduction of raw material costs

- Reduction of waste, energy consumption and energy recovery

- Reduced insurance costs

- Operators are no longer exposed to harmful and hazardous dust or vapors

As demonstrated above, the JOA approach lies not in the straightforward delivery of a standard product. It is our aim to serve as consultants, engineers and industrial filtration system manufacturer. An integrated approach towards the achievement of the best possible solution – first time right.

Future-proofing with knowledge & experience

Currently, JOA sees that many of its clients are already pre-sorting to adapt to recent and upcoming changes in order to create a production process that is future-proof. This enables them to already reap the benefits of an energy efficient production process and a healthy work environment and to ensure that their operation is recognized locally for its positive impact and environmental awareness.

In many cases, such practice goes a considerable way in assisting the company to meet the goals of its own corporate social responsibility undertaking and of the United National Sustainable Development Goals.

With the process described above, JOA develops an in-depth understanding of each system it works with. What this means, is that not only is the company able to supply an optimally efficient, safe and compliant system, it is also able, to quickly assess what is required when it comes to upgrading the system to cope with legislative changes.

JOA takes a forward thinking approach, anticipating changes in legislation in the future. The company makes its systems in a modular fashion, leaving the room required to add additional systems if and when required.

Additionally, JOA’s track record demonstrates its experience in upgrading systems – both those it has produced itself and existing, standard, systems.

Start making your site future proof today. Contact JOA today