How to prevent industrial Dust Explosions

Preventing industrial dust explosions is of utmost importance to ensure the safety of workers, industrial assets and the surrounding environment at industrial production sites. Explosions can result from the accumulation of combustible dust particles, which can ignite and lead to devastating consequences. To mitigate the risk of dust explosions, several key measures can be implemented:

- Source Extraction Equipment

- Housekeeping, e.g by CVC Systems

- Ventilation Systems

- Explosion Safety Equipment

- Clear protocols for handling and storing combustible materials

- Workforce Training & Education to create a safety conscious workplace culture that identifies potential hazards

- Regular inspections, maintenance and risk assessments to identify potential hazards and monitor dust levels

By implementing these preventive measures, industrial production sites can significantly reduce the risk of dust explosions, creating a safer working environment for operators, protecting assets and prevent downtime. Proactive safety measures underscore the commitment to prioritize the well-being of all stakeholders involved in industrial operations.

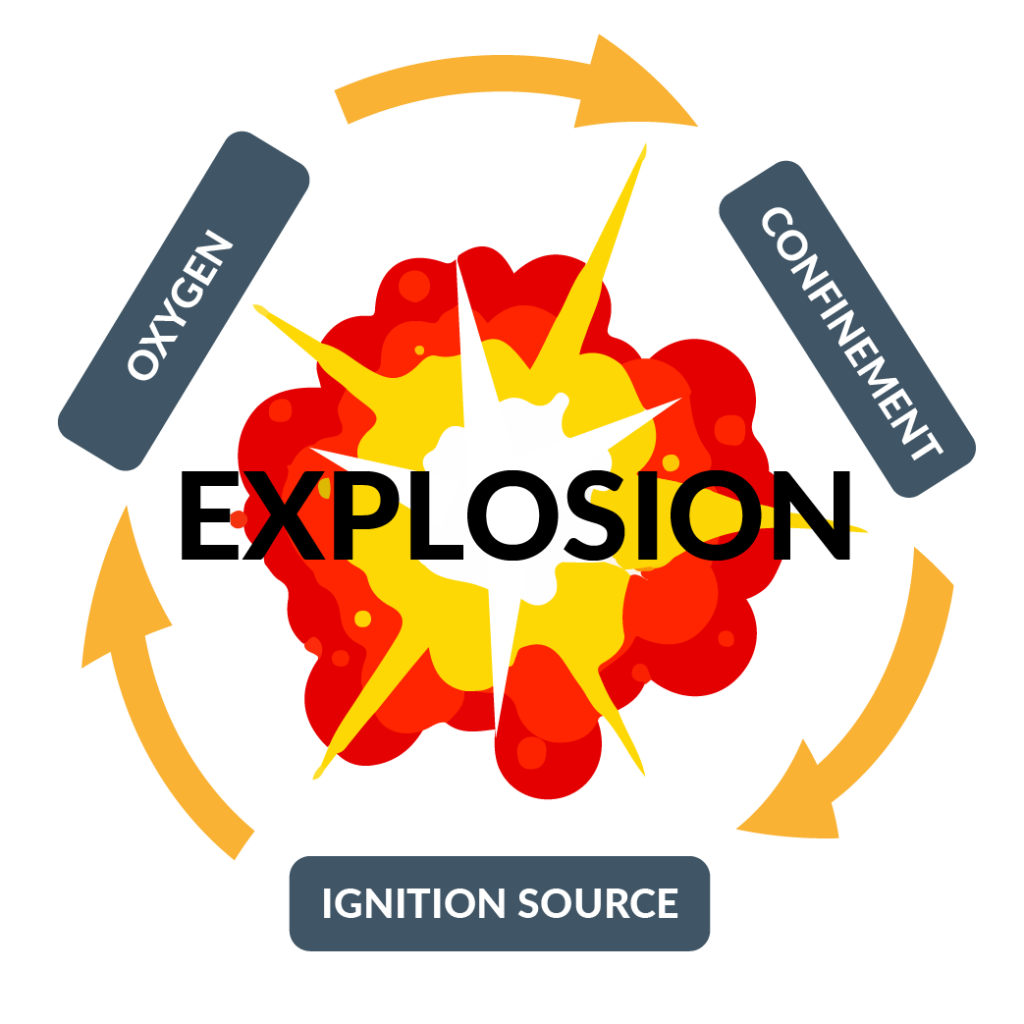

Well known are the three elements of the Fire Triangle: Combustible Dust (fuel), Ignition Source (heat) and Oxygen. Additional elements needed for a combustible dust explosion are confinement of the dust cloud and dispersion of dust particles in the right, sufficient quantity and concentration. Industrial manufacturing processes related to Sugar, Ingredients, Flour, Chemicals, Metals, Bulk Solids, are often prone to create flammable dust.

How to comply with Explosion Zoning directives?

Every manufacturer which is working with or produces a explosible substance (dust, vapor or gasses) will need to comply to the ATEX / Explosion Zoning directives, like the 1999/92/EG, also known as the ‘social directive’ or the 2014/34/EU directive, which is also known as the ‘equipment’ or ‘process directive’. This directive describes the minimum requirements for equipment used in ATEX zones or in which explosive material is handled. This directive is therefore more driven by conformity. Globally, the IECEX certification is accepted and widely accepted as well.

How to reduce Explosion Zoning for industrial sites?

Many companies are concerned about their ATEX zoning. The difference between Zone 21 and Zone 22 quickly runs into high investment costs. Luckily, it’s possible to improve or reduce zoning in a responsible way. For example by implementing balanced dust and fume extraction solutions, possibly in combination with a microclimate. Having an ATEX zone 22 instead of ATEX zone 21 due to better extraction equipment has tremendous economic benefits.

Manufacturers often start carrying out projects to comply with explosion zoning, after which the price consequences for adjusting the equipment and instruments are listed. The shocking costs then often triggers a debate about the interpretation of the regulations. How big are these explosion risks really? It is therefore advisable to start with that question. For the various installations and rooms, this quickly leads to the assessment of the fire triangle, in which oxygen, a combustible substance (cloud) and an ignition source form the three necessary conditions for a possible explosion. If the presence of oxygen (air) cannot be ruled out, one should focus on combating the potential sources of ignition and/or the formation of a combustible dust or vapor cloud. The exclusion of ignition sources is mainly done by explosion containment equipment and upgrading instruments. However, this method is costly, while not removing all sources of ignition. After all, statistics show that not only equipment, but also human actions give rise to accidents.

Methods to reduce Explosion Zoning at Industrial Sites

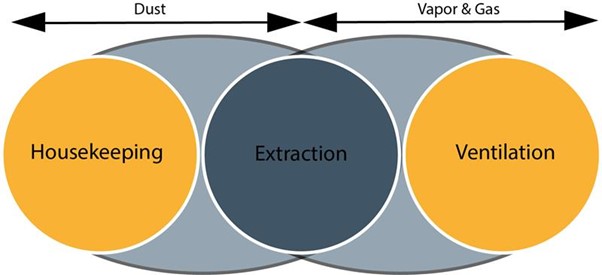

Reduced Explosion zoning can be realized with different interventions depending on whether Dust or Vapor and Gas needs to be handled with (see image below). Before the interventions mentioned below, we always look to eliminate emission sources. This is also in line with the Occupational Hygiene Strategy of involved directives.

-

Housekeeping

Cleaning on a regular basis, using a Central Vacuum Cleaning (CVC) system

-

Source extraction

Eliminating explosive atmospheres at the source by extraction / the explosive atmosphere to dilute the concentration to below LEL value (In an extraction system we want to achieve less than 10% LEL)

-

Ventilation

diluting the working area to avoid explosible concentrations

Learn more about ATEX and Reduced Explosion zoning in our webinar: Watch Webinar on Reduced Explosion Zoning

Effective Dust Collection to reduce Explosion Zoning

For an optimal result, the hood design and air velocities used are essential. The dust extraction system must only remove emissions and not extract the valuable product. It is possible to combine the extraction system with an air intake, since the push effect is stronger than the pull effect. This can create a microclimate in which a lower zoning applies. In many cases, existing equipment, including fans and filters, can be re-used, saving CAPEX costs.

A well-designed system also prevents dust accumulation in the piping, in accordance with Annex II H1.2.4 of the ATEX Directive. Such accumulation or growth of dust due to crystallizing or condensing vapors poses a great risk for secondary explosions. It is therefore crucial that certain air velocities in the system are guaranteed.

JOA is able to monitor and validate these parameters and processes remotely automatically with Air Flow Measurement Units. This means that quality assurance is included with the solution. In combination with Air Technical Modeling, flow rates can be adjusted and balanced. Using patented designs, the right pressures and volumes can be extracted.

Pre-Engineering Study

Cost savings resulting from better ATEX zoning, in combination with additional benefits, must outweigh the investment for a dust- or fume extraction system. Whether this is to be expected, can be investigated through a Pre-Engineering Study. This first step helps us understand the situation by conducting a site visit, take measurements, identify bottlenecks and create a Budget Quote and Concept Design validated by Air Technical Modelling.

This proven methodology assesses whether explosion zoning can be improved based on dust emissions. The study starts with an investigation of the extraction points / sources and associated emissions. It then determines what the correct extraction system will look like, including the corresponding capacities and air technical parameters. The concept design of the extraction system then looks at the total air management within a site. Mapping ventilation rate in combination with the balance between inlet of outside air and the norm helps finding solutions. Sometimes, the inlet air needs to be pre-heated (also see Energy Recovery Systems).

Additional benefits of Explosion Safety Compliance

- Healthy Work Environment

- Compliance with MAC values

- Less environmental emissions

- Cleaner Production Environment leads to more happy operators

- Reduced Maintenance Costs

- Less unpredicted downtime

98+% source elimination

Prevent combustible dust

Acoustic Agglomeration is known as a powerful method to battle ultra-fine particulates by sound waves. To prevent UFP's and aerosols, which have direct adverse effects on company members, read JOA's paper which addresses an integrated solution that protects workers.