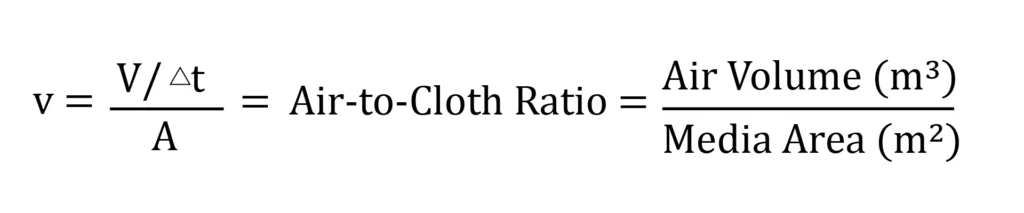

When designing and intergrading dust collectors in dust collection systems there is an important factor that requires careful consideration, the Air-to-Cloth Ratio. This ratio can determine the efficiency of a dust collector. As when this ratio is out of balance or calculated wrong it can create issues or reduce the lifetime of the filter media.

Air-to-Cloth formula

The air-to-cloth ratio is the volumetric flow rate of air (m3/minute; SI m3/second) flowing through a dust collector’s inlet duct divided by the total cloth area (m2) in the filters. The result is expressed in units of velocity. Basically, meaning how much air passes through each filter per square meter. This gives the following formula which can be broken down in 3 steps:

- Determine the total airflow rate in cubic meters per minute (m3/min).

- Determine the total filter area in square meters (m2).

- Divide the airflow rate by the filter area to get the air-to-cloth ratio in meters per minute (m/min).

For example, if a dust collector has an airflow rate of 100 m3/min and a filter area of 50 m2, the air-to-cloth ratio would be 2 m/min.

What Happens When the Air-to-Cloth Ratio is too Low?

When the air-to-cloth ratio is too low, it typically means that there is more filter media for the amount of air and dust that enters the dust collector. In general the higher the ratio the better With an Air-to-Cloth ratio that’s too low you might encounter issues like:

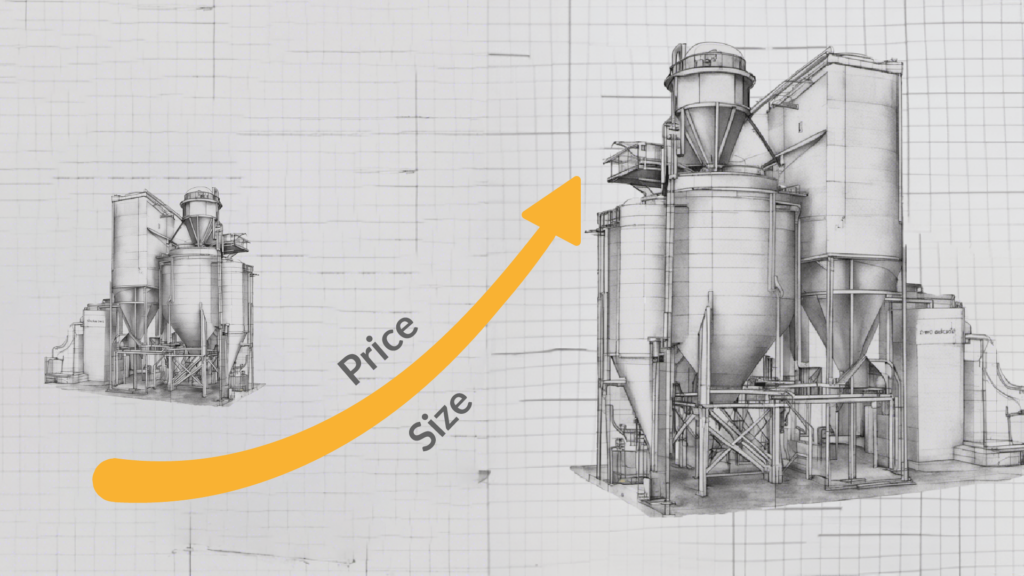

- Inadequate Filter sizing: When the filter is improperly sized the initial acquisition cost of the dust collector can increase quickly. As with larger filters comes more filter media which are more costly.

- Increased Footprint: Having more filter media requires enlarging the filter housing, which in turn, makes the filter unit larger and takes up extra space. This can be problematic when the production site is already full with machinery and piping.

What Happens When the Air-to-Cloth Ratio is too High?

When the air-to-cloth ratio is too high, it means that there is too much air passing through the available amount of filtration media. Having an Air to Cloth ratio that’s too high isn’t ideal either. In such cases, you might encounter issues like:

- Increased Cost: The pressure drop across the filters will be too high, which can increase the energy consumption and operating costs of the system. As the fan needs to work harder to push or pull the amount of air.

- Decreased Filter Life: The filter clogs quicker, as the dust is driven deeply into the filter. Therefore, the media cannot be cleaned by the pulse jet system, and the frequent and intense pulsing will wear out the filter media and cause early breakage. This leads to more frequent filter replacement.

- Decreased filter efficiency: The dust capture efficiency will be decreased, as the dust will travel through the filter media at higher speeds or UFP’s will escape. This results in the release of particles into the surrounding environment.

Finding the Right Balance

To optimize your dust collection system’s performance, it’s essential to find the right balance in Air-to-Cloth Ratio. To mitigate the effects of a too high or too low Air-to-Cloth ratio. JOA Air Solutions calculates the ratio for each specific application through careful design and engineering. This involves selecting the right filter media, ducting, and airflow controls to ensure efficient and compliant operation while maximizing filter lifespan and energy efficiency.