Table of Contents

The demand for filters or emission control solutions is on the rise. Ever more stringent legislation and more responsibility to look after workforce and assets, have led manufacturers all over the world to improve their air quality and extraction systems. Also, costs of resources and energy are higher than ever.

This means that we receive many requests for quotations at JOA. We are thankful for this, but not all requests are as suitable as others. Over 25 years, JOA has specialized in certain specific segments where we believe we can add the most value. Also, our approach and way of working requires a certain commitment from clients, which is not always a good match. Please find below the 5 most common reasons when not to choose JOA Air Solutions for your emission control challenges.

Smaller size production processes

Many of our clients are leaders in their industry with large and complex production processes. They continuously scout for new technologies every day to enhance their operations to satisfy their stakeholders and because the whole world is watching them. They feel the responsibility of maximizing the potential of their resources and assets.

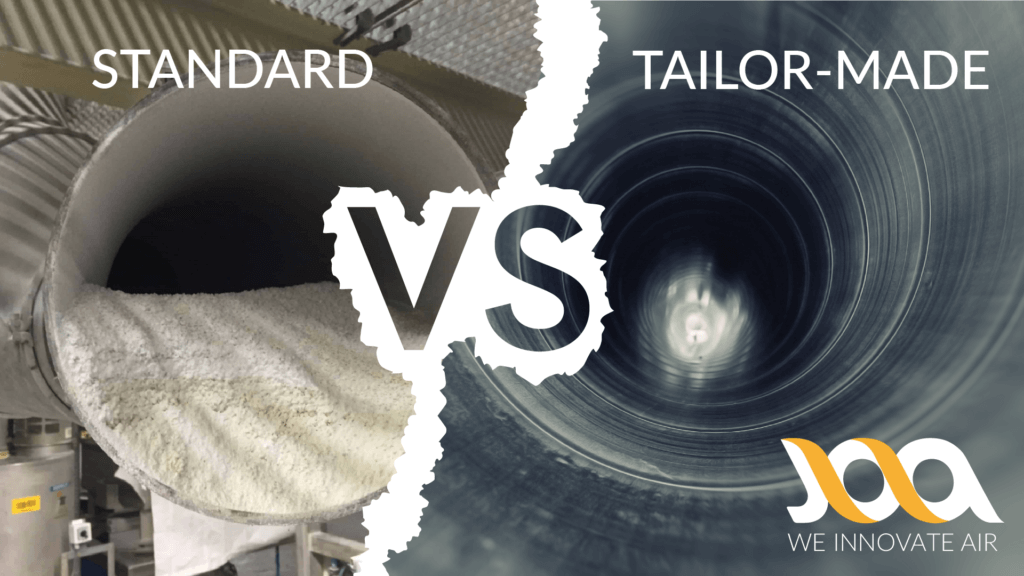

Improving efficiency in processes and reducing waste can have significant effects, just as creating healthy work environments and protecting operators and the site from dust explosions. Due to the size of these leading manufacturers in combination with the extraction volumes in m3/ft3, they can afford tailor-made solutions. Although the initial CAPEX investment may be higher, the total cost of ownership will be lower over time. Creating higher value in the long run is more important than achieving short-term results.

This is why JOA Air Solutions only works on solutions for the largest and most complex industrial production processes. A new client rarely has a revenue below €300 million annually. By being selective, we are able to keep our focus on less projects of larger size without being distracted or need to standardize our operations. Attention to finding the best possible solution for manufacturers always remains the top priority.

When production volumes are low, a tailored system is not a great fit and a more standard supplier will suffice. Industries like Biotech or Pharmaceuticals will often choose different solutions like complete cleanrooms. Below a selection of clients that suits us perfectly:

Low value product or resources

The manufacturing industry is versatile but has much in common regarding a focus on efficiency, energy consumption, safety and a need for quality.

Industries with lower product or resource values often have higher volumes and flow rates. Large dedusting or scrubber systems are needed and there is less demand to get the size exactly right. Over-dimensioning and standardized solutions will often do fine. To summarize, JOA is almost never successful when asked to solve dust related challenges related to the following industries:

- Cement

- Woodworking & Furniture

- Welding fumes

- Minerals

- Ceramics

- Beverages

- Biotech & Research Laboratories

- Oil & Gas

There are some gray areas like building materials, Recycling, Steel or Aluminum. They are facing rising demands on pollution, emission control and waste heat recovery. Well-known polluters from these industries have found their way towards JOA, when they are willing to invest in finding the best possible solution. A pre-engineering study will assess the possible returns and guarantee future performance.

Companies that do not match our tailored proposition will frequently be better off choosing a more standard solution. Please also read our blog about the Top 5 standardized Air Filtration companies. Manufacturers from industries related to Chemicals, Food Production, Pharmaceuticals, Plastics, (Building) Materials, Paints & Coatings, Ingredients, Tobacco or some consumer goods are mostly a good match for tailored emission control.

Co-operation with third parties, like Engineering companies, Consultants and Machine Builders

There are many large engineering companies that assist manufacturers with construction of new sites, large update programs, or production lines and much more. They are generalists with a large workforce with a lot of general knowledge withing several segments.

When Engineering companies face more complex challenges regarding dust or fume emissions, they tend to partner up with specialist firms, like JOA. We are frequently asked if we have a solution for certain issues related to dust, fumes, clogging, energy recovery, explosion safety and more. We then ask several questions to be able to give them the best possible answer. This requires a lot of time, effort and might lead to miscommunication.

When pursuing opportunities with third parties, we learned that only 10% of all requests were successful. As a comparison, we normally convert over 40% of all requests we receive from new potential clients in our targeted segment. We experience it’s hard to explain our added value when we are not able to directly talk to the engineers of the end-client.

Therefore, we generally handle the following criteria when cooperating with 3rd parties:

- The end client name and site location is known and shared. This is required for us to qualify if there is a match or not.

- The end client production process matches criteria regarding size and segment (see items 1 & 2 above).

- The end client is willing to conduct a Pre-Engineering Study in advance of Systems Selection.

- JOA is able to directly communicate with the end-client.

By being strict on these criteria, we can commit to realizing the best possible solution for the end client. Close cooperation with other suppliers is a practice we are well acquainted with. Frequently, this leads to long-lasting partnerships. Utilizing diverse disciplines and expertise from various partners is in the core DNA of JOA Air Solutions.

Focus on prize, instead of focus on a quality solution

It’s human to focus on costs. Looking at the prices of a dust collection system or industrial scrubber is an important decision, especially as it will not always immediately add to higher returns. Only in the long run, the solution with the higher investment may prove its value. Especially when purchasing is involved, it might be hard to explain what extra value a tailored solution may entail. We see it as our responsibility to provide you with the necessary ammunition to make the right decision.

A Pre-Engineering study helps (Process) Engineering to explain how a slightly higher CAPEX solution leads to a lower Total Cost of Ownership (TCO). We understand that you and your purchase department are used to working in a more standard way with ‘price’ being the biggest denominator. By clearly predicting future results and providing process guarantees, you will be able to make better decisions. Also, you will know what the investment will be to truly solve your problem, in relation to the value of the benefits.

JOA has embraced we will never be the Emission Control specialist with the lowest prize. We are however committed to being the company that’s able to offer industrial manufacturers the highest value for their investment. This way we can stand above mediocrity and standard suppliers of filter systems.

When a client has a focus on prize, we always lose.

Bas van den Bogerd, Business Development Director

When there is a focus on quality and Total Cost of Ownership,

we almost always win

Air Filter Manufacturers

We are frequently contacted by manufacturers of Air Filters and Filter Media from all over the world. They ask us if we are interested in integrating their filters into our solutions. Even though we are always open to learning more about the capabilities of Original Equipment Manufacturers (OEM’s) like filter manufacturers, we found that our current preferred partners offer the best possible filters for the systems we design.

We believe the most impact is created by adjusting the use of filters from a more holistic view, based on thorough understanding of the production process. This is defined during a Pre-Engineering Study, including Air Technical Modeling.

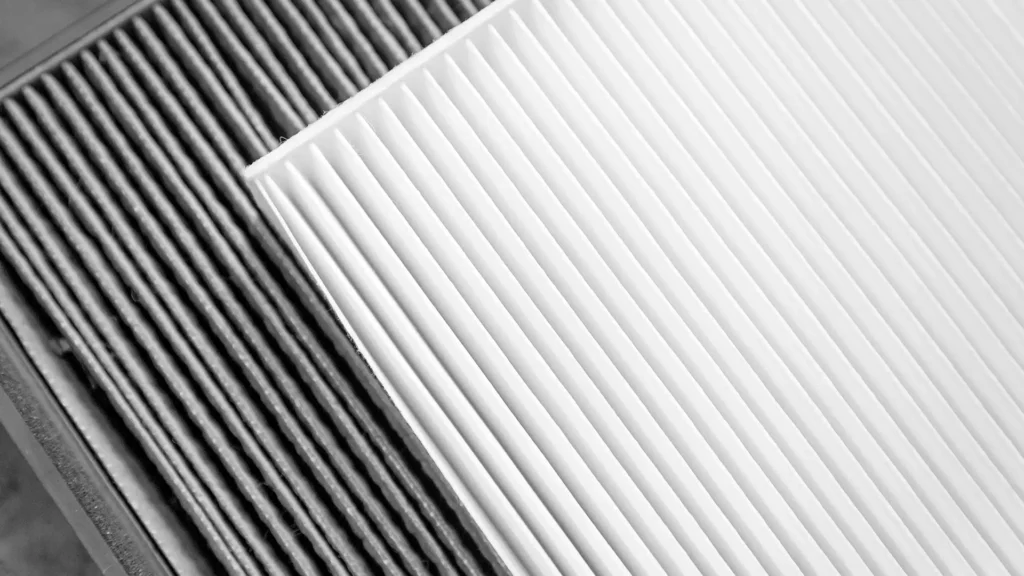

Also, to address more specific requests and to provide the most optimal solutions, we’ve developed (patented) filter designs. These designs incorporate a variety of media types, finely tuned to match particle characteristics, flow rate and energy efficiency. Depending on the situation, we can decide what kind of filters work best. By remaining independent, we are not limited to the portfolio of standard filtration manufacturers, like these Industrial Air Filtration Suppliers.

Looking for a quick fix with standardized products

Unlike the conventional approach where engineers often request quotes from multiple suppliers and choose based on price alone, JOA Air Solutions follows a different approach. We understand that providing a mere price estimate without a comprehensive understanding of the specific industrial context will not result in the most optimal solution. That’s why we emphasize a thorough dialogue, rather than offering quick quotes.

After an initial meeting we often conduct a site survey as part of a Pre-Engineering Study. This approach allows us to gain deep insights into our clients’ unique challenges and processes, ensuring that the solutions we deliver are not only cost-effective but also precisely tailored to all requirements. The result is that quality and long-term performance is put in front of the simplicity of rough price estimations.

We understand that there are many people responsible for a site’s operational performance and Emission Control is just a small part of their daily job. When searching to upgrade or replace your current dust collection or fume extraction equipment, you might want to get a quick overview of price, capabilities and preferably some references from your competitors. You’re likely to find yourself talking again with one of the larger suppliers all offering similar solutions and quotations, presumably ‘customized’ to your needs.

When you only worked with Dust Collection Systems or Scrubbers from one of the Top 5 Standard Industrial Extraction Suppliers and are used to the problems that may occur with these standard systems. It seems only natural to have regular clogging, downtime for maintenance and a full team frequently doing housekeeping to remove dust.

In other situations, like Pilot Plants or Greenfield sites, not all data is available yet. A more standard and cheaper solution is often chosen to begin collecting data. When there is funding and knowledge from other sites with comparable processes, we are able to cooperate and create first-time right solutions. Most of our projects involve brownfield sites though.

No production process at all

In some cases, we are contacted by parties that do not have an industrial process at all or manufacturing processes with other demands. In other cases, production is mostly enclosed, making dust less of an issue. To summarize, we do not offer solutions related to the following business areas:

- Airports

- Hospitals

- Restaurants / Public areas

- Office spaces

- Schools / Universities

- Automobile

- Logistics and Warehousing

- Beverages

Are we a good match? Please share your challenges with us!

Did you walk through all 7 items and still think we are a good match? Great to hear! Please get in touch and share your challenges! We look forward to optimizing your processes with the best possible solutions for dust, fumes and energy efficiency.