Indoor and outdoor emissions are a critical concern in industrial manufacturing, with airborne pollutants, odors and volatile organic compounds (VOCs) creating risks for human health and the environment. To address this challenge, various air filtration technologies can be considered, and one effective and sometimes more cost-efficient method, compared to scrubbers, is the use of active carbon filters.

What is Activated Carbon?

Activated carbon is a highly porous form of carbon that has undergone a process called activation. This process involves treating organic materials, such as wood, coconut shells, peat, or even coal, with high temperatures and sometimes chemical agents to create a network of small pores. This maximizes the surface area which can be used for adsorption of contaminant particles. The resulting activated carbon is known for its exceptional adsorption properties, making it effective in various applications for removing impurities, contaminants, and pollutants from gases, liquids or a mix between these two (solution).

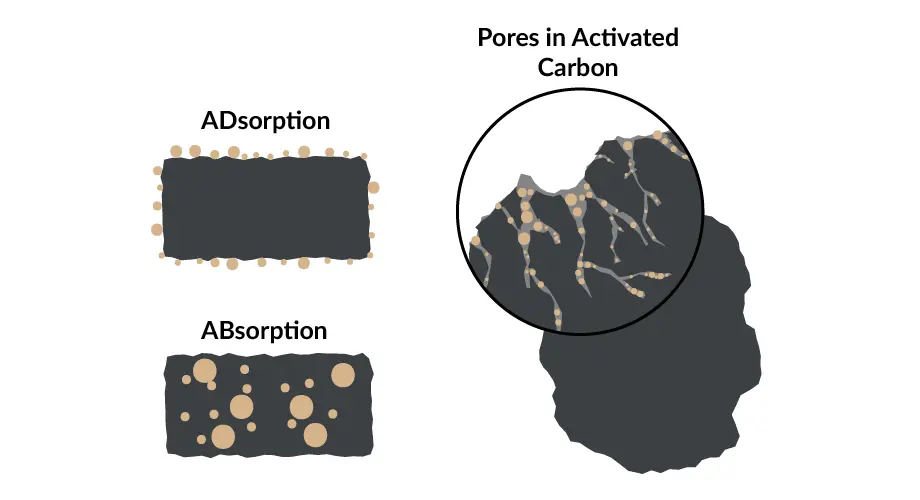

- ADsorption: A surface phenomenon where pollutants adhere to the surface of a solid or liquid without becoming part of the sorbent material.

- ABsorption: A process where pollutants dissolve into or permeate through a liquid or solid material, becoming part of the absorbing substance.

The pores in activated carbon can vary in size and distribution, contributing to its ability to adsorb a wide range of molecules and particles. The surface area of activated carbon can be immense, often exceeding several hundred square meters per gram of material. This huge surface area provides more than enough space for molecules to adhere to the carbon surface, either through physical adsorption or, in some cases, chemical reactions (attraction).

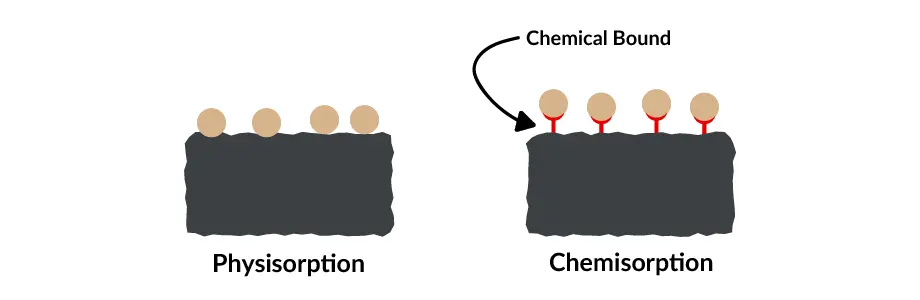

- Physical Attraction (Physisorption): Molecules attach to the activated carbon’s surface due to weak forces, e.g., ‘Van der Waals’ interactions. This is a surface-level interaction and doesn’t usually change the molecules’ properties.

- Chemical Attraction (Chemisorption): Molecules form strong chemical bonds with the activated carbon’s surface, often changing the molecules’ properties. This involves a more significant transformation and can result in a lasting connection.

* Do note that these two are examples of ADsorption and not to be confused with ABsorption.

Types of Activated Carbon Filters in Air Filtration

When it comes to air emissions, activated carbon filters are used in chemical, food, oil and gas industries to capture and remove airborne pollutants, volatile organic compounds (VOCs), odors and other contaminants. With the use of activated carbon filters, it is possible to reduce inside and outdoor emissions. A few common types of active carbon (AC) filters used in the industry are as follows:

- Powder Active Carbon: Such AC comes in the form of very fine powder, and it is rarely used in the form of a cartridge filter as it can cause high pressure drop. Instead, it is applied directly on filtration media, such as for gravity filtration or in a clarifier.

- Granulated Active Carbon: Granulated AC comes in larger particles compared to powder AC, and as such it can be contained in cartridges or a filtration bed and used for air filtration (e.g., deodorization).

- Pelletized Active Carbon: By extruding a mixture of AC powder with binding compound, larger AC pellets can be produced. Due to the low pressure drop characteristics, it is often used for both gas and liquid media filtration.

- Active Carbon cloth: AC can also be made as fibers and woven in cloth-like material, which can then be used as filtration device for contaminated air or other gases. AC cloth is also widely used for medical and pharmaceutical purposes.

Active Carbon can also be infused with additional elements such as silver or iodine to enhance the adsorption capability for specific contaminants (e.g., hydrogen sulfide, ammonia, metal oxides, etc.).

How does an Active Carbon filter work?

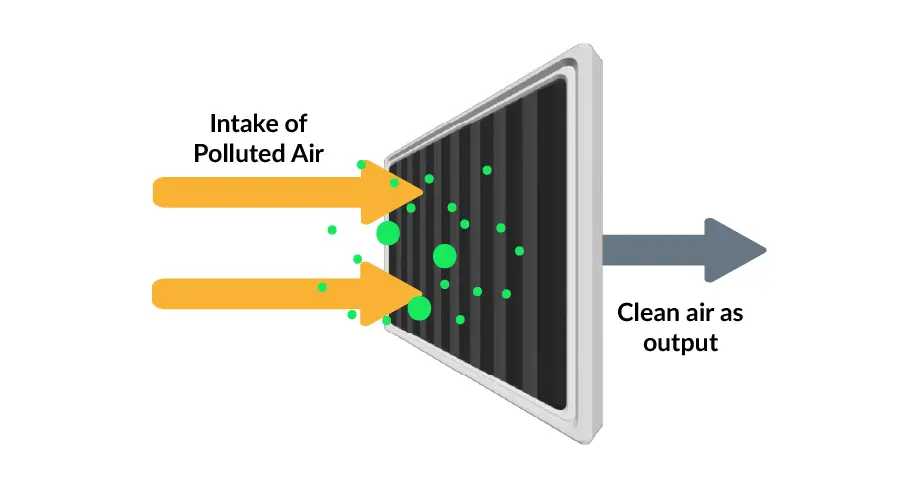

A general activated carbon filter used for air emissions works by adsorbing airborne pollutants, volatile organic compounds (VOCs), odors and other contaminants from the air. Here’s how the process works:

Intake of Polluted Air:

The contaminated air containing pollutants, VOCs, and odors is pushed into the activated carbon filter. Inside the air filtration system, the air passes through a bed of activated carbon. The activated carbon can be in the form of granules, pellets, or other configurations. As the polluted air flows through the activated carbon bed, the contaminants come into contact with the carbon’s surface and pores. The contaminants will bond to the activated carbon via Physisorption (weak) or via Chemisorption (strong).

Clean air as output:

The air that exits the activated carbon filter contains significantly less contaminants. Nevertheless, over time, the pores of the activated carbon can become saturated with captured contaminants. This decreases the filter’s efficiency. Depending on the application and the concentration of pollutants, the activated carbon filter may need to be replaced or regenerated when this happens.

When should you apply Activated Carbon Filter

It depends on your specific needs. An active carbon filter can work perfectly in certain circumstances, but other times different solutions can work better. For instance, in one case a specific characteristic of an AC filter can be beneficial and in another situation it can be bad. When you are deploying Active Carbon Filters in your manufacturing process, it can be a viable solution. But the effectiveness and the right fit depends on the situation.

Characteristic of an Activated Carbon Filter

- Targeted Adsorption: Activated carbon’s effectiveness depends on the nature of the contaminants. It may not effectively capture certain inorganic compounds or highly polar molecules.

- Low volume: Suited for low volume air flows

- Low Energy Consumption: Activated carbon filtration typically operates at ambient temperatures and requires minimal energy input compared to other technologies. But only when low flow throughput is concerned.

- Physical Footprint (size): compared to different filtration installations AC filters are generally compact in footprint and they do not require any additional utilities.

- Modularity: Activated carbon filters can be designed in modular configurations, allowing for scalability and adaptation to changing emission rates.

- Installation: Implementation of activated carbon filters often involves shorter setup times compared to more complex air pollution control technologies. Activated carbon filters can be integrated into existing systems or retrofitted into various industrial processes with relative ease.

Things to consider with using Active Carbon filters

- Type of Contaminants: The specific pollutants, VOCs, and odors present in the air emissions determine the type of activated carbon and its pore size distribution that will be most effective.

- Resident Time: The duration the polluted air spends in contact with the activated carbon significantly impacts adsorption efficiency. Longer contact times improve adsorption, but proper flow dynamics are crucial.

- Temperature and Humidity: These factors affect both physical and chemical adsorption processes. Higher temperatures might increase desorption, while humidity can impact adsorption capacity.

- Maintenance: Regular monitoring, maintenance, and replacement of filters are essential to ensure consistent and effective performance. However, keep in mind that replacing filters can lead to recurring costs. Higher concentrations of pollutants can lead to quicker saturation of the activated carbon, requiring more frequent replacement or regeneration.

- Regeneration Challenges: While the energy consumption of AC filter during its operation is minimal, the regeneration of AC filter can be energy intensive. Impregnated or specialized carbons may have limited regeneration potential.

- Regulatory Requirements: Meeting specific regulatory standards for air quality and emissions may dictate the design and performance of the activated carbon filtration system.

- Environmental Impact: Disposal of spent activated carbon, especially if it has adsorbed hazardous substances, may have environmental implications.

- Health and Safety: Dust generated during handling of activated carbon or spent carbon can pose health and safety risks to workers.