Nobody likes a dirty workplace

Dust can be a real nuisance at production sites. Besides being bad for the health of your operators, dirty environments can cause a real safety issue. Unhappy workers and wasting both time and resources will eventually lead to inefficient processes.

To solve this challenge, there are basically two solutions:

- A portable vacuum cleaner: generally sufficient for cleaning single machines and accessible areas.

- A Central Vacuum Cleaning (CVC) System: In larger production areas and areas with mezzanine floors, where mobile vacuum cleaners cannot access easy, a central vacuum cleaning systems proofs to be a better solution.

Comparing portable devices with Central Vacuum Cleaning Systems

Both solutions are able to do the job. However, Central Vacuum Cleaning Systems are often more convenient and have the following benefits over portable devices.

- Up to 100 vacuum cleaning points can be created

- Hose length up to 10 meters. Making it easy for maintenance to clean.

- Increased Product Quality and Less Cross-contamination as the exhaust of the Central Vacuum Cleaner is placed away from the production process. UFP’s, germs, bacteria and gases are removed from the site, where portable devices are recirculating the air back into the workplace.

- No power cords over the floor, getting stuck or creating trip hazards. No more dragging heavy machines up and down stairs.

- More efficiency compared to portable devices, due to larger waste bins, at a singular point.

- One central system is easier to use and takes up less space

- Possible reduction in Energy, Maintenance and Monitoring costs can be realized.

- CVC Systems are robustly built to operate 24/7

Why choose JOA for your new Industrial Vacuum Cleaning System

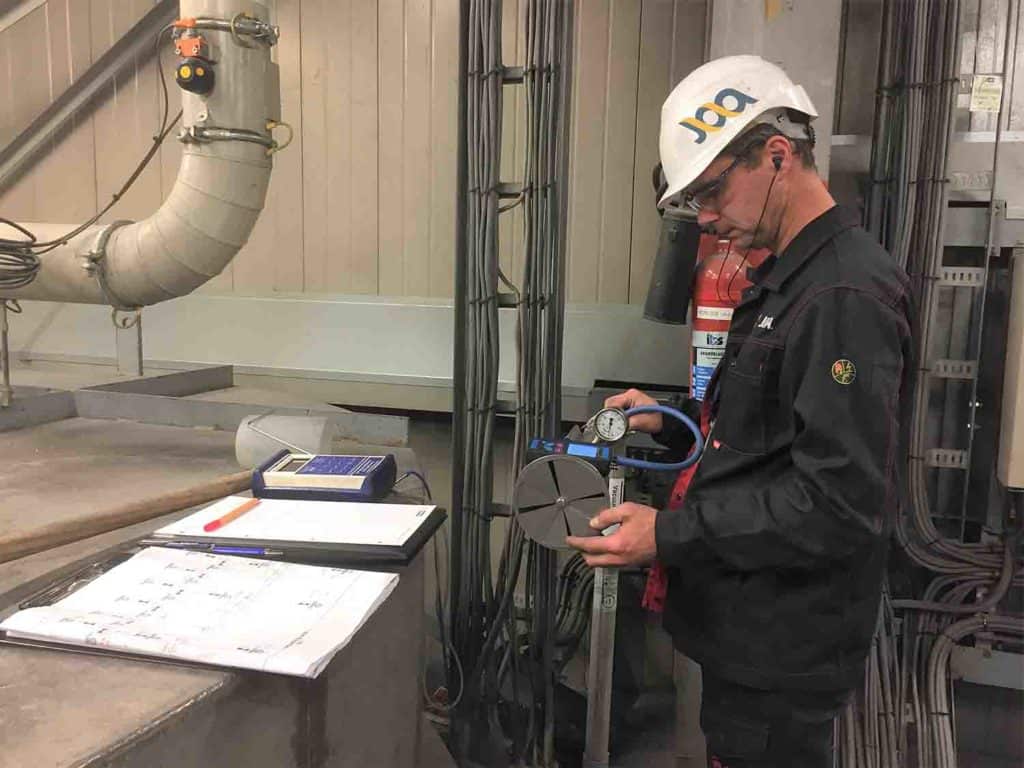

We truly want to understand your specific challenge. Our specialists take the time to investigate particle characteristics, visit your site and interview your operators, before coming up with solutions.

Having implemented and upgraded over 70 Central Vacuum Cleaning Systems for manufacturing sites worldwide, we know how to deal with your sites specific requirements.

- Designed for your site’s specific requirements. Ducting is installed so that all workplaces are easily accessible.

- Guaranteed balanced and stable vacuum at multiple cleaning points that can be operated simultaneously.

- Strong vacuum with high capacity. We use generally a minimum of 250 m3/h at an under pressure of 5000 Pa at the extraction point.

- Long reach: We have realized stable and reliable vacuuming at more than 100 meters from the filter by using false air valves that keep negative pressure and extraction velocity constant and at an optimal speed.

- Filter life extension and emission limits guarantee

- ATEX Compliancy through robust design and explosion venting to the safe area (outside) or by flameless venting (inside). Further explosion protection with back flow or float valves.

- Built in the Netherlands according to the highest quality standards

An central industrial vacuum cleaning system is part of a larger dedusting strategy. It should be combined with effective dust collection, good housekeeping and source elimination by process improvements.

Don’t let dust cause your operators and site any harm

Not being able to get control on dust emissions and being annoyed by the inefficiency of portable devices can lead to a lot of frustration. More than 30% of all manufacturing sites we encounter, do not have control over their workplaces.

Nobody wants to work in a dirty workplace. Combined with the uncertainty of explosion hazards, operator turnover or unpredicted downtime due to cleaning or maintenance can really have a large impact on your site’s performance. Continue working with inefficient and unorganized procedures. The health and happiness or your operators is at stake.

JOA offers clear insights in where to improve dedusting and is able to predict clear future outcomes so you can be sure of the effect of our solutions.

Realizing a clean, safe and healthy workplace for your workers leading to better operations

Every site and production process is different. Our approach guarantees an easy accessible, well thought out system with multiple cleaning points. This results in happy, healthy and effective workers. Being fully compliant to Emission Limits and ATEX legislation, gives you the certainty of safe and efficient operations. Clean environments improve product quality and process performance.

JOA has a vast track record with the extraction of dust within multiple industries, like: Food, Chemicals, Ingredients, Sugar, Starch, Feed, Tobacco, Materials, Toner, Paint and other Bulk Solids. Next to designing, building and implementing Central Vacuum Cleaning Systems, JOA also offers predictive maintenance, additional process upgrades and spare part services.

Dust Extraction at the source

In most cases, a dedusting system will extract most of the dust, but often a vacuuming cleaning system is required to clean spills from floors, beams and equipment. At JOA, we offer a full package of Extraction Solutions, Services and Products to prevent dust being emitted at the source or to the outside environment.

What is a Central Vacuum Cleaning System?

A central vacuum cleaner is a type of vacuum cleaner appliance, installed into a site as a semi-permanent fixture. CVC systems are designed to remove dirt and debris from workplaces, sending dirt particles through tubing installed inside the walls to a collection container in a remote utility space. The power unit is a permanent fixture, usually installed in a basement or storage room, along with a collection container. Inlets are installed in walls throughout the building that attach to power hoses and other central vacuum accessories to remove dust, particles, and small debris from interior rooms.

How does a Central Vacuum Cleaning System work?

JOA always designs central vacuum systems in close consultation with our clients. Together we determine the position of the vacuum contacts. Important is that all machines, platforms and the entire floor area are within reach with the vacuum hoses and the accessories.

All vacuum contacts are connected to the central vacuum cleaner and blower by a large pipe system. The Industrial Vacuum Cleaning System consists of a JOA filter unit with sinter-plate filter media and a blower or fan that creates the required pressure. The collection unit is where the vacuumed dust is collected. This can be big bags, hoppers or removable steel containers.

4 Tips when selecting an Industrial Vacuum Cleaning System

When looking for a central vacuum cleaning system, there often are some specific things to take in mind:

- Take a good look at Product Characteristics: basically all products that might be present somewhere in the building might be cleaned up.

- Smoldering material might be cleaned up as rare faults. For example when dust is cleaned up from a hot surface. This may affect your system requirements. Therefore it is recommended to protect these filters with explosion protection.

- Make flexibles Anti-static: With vacuum cleaners there are always flexibles. Meaning it is very important that all flexibles that will be used for vacuum cleaning are anti-static.

- Save costs by carefully select Filter bags: Filtered systems use a wide variety of different bags or filters that must be cleaned (permanent cloth bags) or replaced (disposable paper bags) on a regular basis. Filters can be made from screening, foam, paper, or cloth, and are usually proprietary designs that may not be widely available. Over time, repeated purchase of filters and bags can become significant ongoing expenses.