According to the National Fire Protection Association (NFPA), a room with at least 5 percent of its surface area covered with more than 0.79 mm (1/32nd of an inch) of organic dust presents an explosion hazard. So even with a thin layer of dust in a confined room, a blast may occur if the dust becomes airborne and is ignited by potential sources such as sparks, open flames and electrostatic discharge.

Understanding the dangers of combustible dust

Combustible dust can put factory workers in mortal danger. Dust can accumulate within the factory and can become explosive. Between 1980 and 2017 386 combustible dust incidents were reported in the US only. On average 30 explosions happen each year. Which resulted in 64 fatalities in 2021.

What is combustible dust?

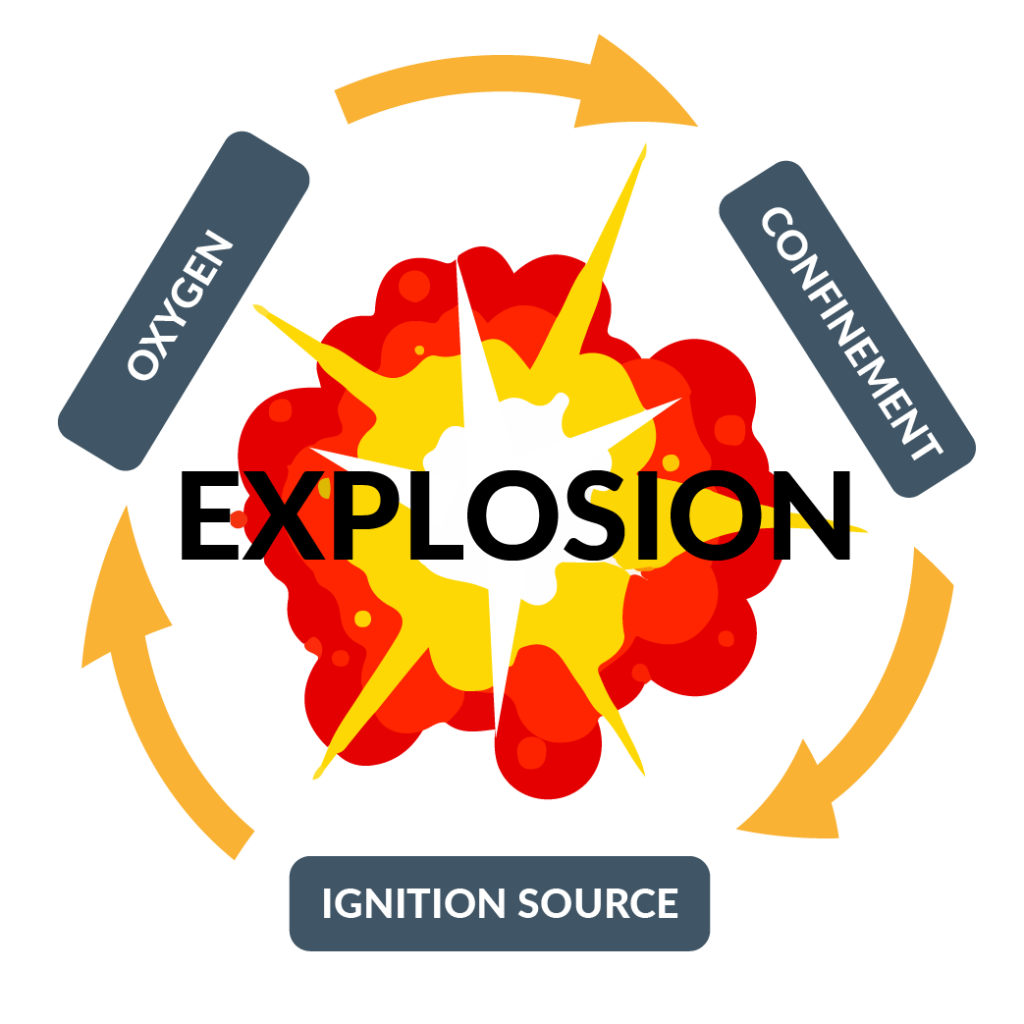

Combustible dust is a solid matter composed of distinct particles that will combust when suspended in air in high concentrations. Combustible dust explosions occur when five elements are present. When you have dust in sufficient concentration and quantity, an ignition source and oxygen within a confined space an explosion will occur. If one of the above five elements is absent, an explosion cannot happen. However, once the primary explosion occurs, a secondary one may strike the factory even more destructively because other dormant dust has been activated and becomes airborne and ignited.

Dust is created when materials are transported, processed, polished, ground and shaped. When dry materials are crushed, mixed or screened, dust is generated. Within the food industry you have many kinds of combustible dust, some examples are:

- Sugar

- Starch

- Flour

- Protein powder

- Milk powder

- Cocoa

- Coffee

- Certain herbs

Also in other industries combustible dust can be an issue. Like within the Chemical manufacturing, Tobacco, Plastics, Consumer Goods, metal processing, recycle facilities, woodworking facilities and coal-fired power plant.

Damage Control

Industrial dust explosions are a serious concern across industries, posing risks to property, equipment, and safety. To mitigate these risks, manufacturers must understand the underlying causes.

How can workers be protected?

We can prevent combustible dust from accumulating. The Occupational Safety and Health Administration (OSHA) and the NFPA recommend some approaches to protect work environments from a dust explosion hazard. Below a few ways to prevent dust from accumulating.

1. Dust Control

First, in order to minimize dust accumulation, utilize smooth ceilings and sloping surfaces rather than rough ones. If possible, put covers around pipes and cables, or embed them in the walls. Second, inspect and clean up dust residue regularly, especially in hard-to-reach areas. Third, minimize the escape of dust from equipment and ventilation systems.

2. Proper Dust collection

Use proper dust extraction and collection system. Install the inlet as close to the dust producing process as possible and locate dust collectors outdoors if possible. Only utilize specialized vacuums approved for dust collection instead of using brooms or compressed air hoses to clean surfaces, which may generate dust clouds.

3. Machine Maintenace

Maintaining is important in preventing explosions in factories. According to ISO 19353:2019, a standard for safety of machinery and fire prevention/protection. Operators should regularly inspect, clean and repair any necessary parts to avoid dust build-up, that could turn into an explosion hazard.

4. Regular Cleaning

Keeping things clean is a big part of prevention. If there’s no dust around, there’s no chance of a dust explosion happening. When there is still dust accumulating on factory floors, which is not collected by dust collection systems. One should remove hazardous combustible dust through regular and thorough cleaning. Otherwise, these dust piles can cause fires and explosions when there is an ignition source nearby.

5. Operator Training

Employees play a crucial role in preventing and dealing with fires and explosions, particularly those related to combustible dust. Operator training is essential as they are often the first to recognize hazards. While OSHA requires training for specific employees, all workers should receive training in safe practices for their tasks, as well as broader dust control and ignition source management. Training should occur before work begins, periodically for refreshers, upon reassignment, and when hazards or processes change. Employers handling hazardous chemicals, including combustible dusts, must comply to the Hazard Communication standard (29 CFR 1910.1200), which includes labeling, material safety data sheets, and employee training requirements.

6. Explosion prevention

Remove open flames, sparks, friction, heat sources and all other sources of ignition. Make sure all mechanical and electrical equipment is maintained properly. Keep static electricity under control. Ensure that equipment and machinery are properly grounded and bonded to prevent the buildup of static electricity, which can ignite dust particles. Make sure the factory has isolation barriers and workers are using the appropriately designed screw conveyors.