The requirements for heat used in production processes or heating is often very demanding. The right implementation of Heat Pumps can often help reduce costs and reduce environmental footprint. Thanks to their efficiency and high return on investment, they provide an efficient and economical alternative for traditional heating systems.

Overview of the best Industrial Heat Pumps Suppliers

Nobody wants to make wrong decisions. For multiple projects, we have assisted manufacturers by making a selection of a variety of Heat Pump System suppliers. We normally evaluate them based on:

- Efficiency: indicator of equipment thermodynamic efficiency evaluated based on Carnot efficiency.

- Refrigerant type: Traditionally, heat engines (heat pumps and chillers) operate using high GWP and ozone-depleting refrigerants which are no longer considered sustainable. Newer equipment is expected to be more environmentally friendly and with minimal toxicity and flammability

- Capacity: For industrial applications, heat transfer in the order of hundreds of kW to a few MW is very common. Prototypes are often manufactured at smaller capacities. Therefore, it’s desirable to identify suppliers that have scaled up their equipment.

- Supply temperature: Many sites use medium to high pressure steam supply. Depending on requirements a lower or higher temperature output is preferable.

- Technology Readiness Level (TRL): Measures the maturity of a technology from conceptualization towards commercialization. A higher TRL is often more reliable and robust technology with lower delivery times.

Criteria to make the right choice between Heat Pump suppliers

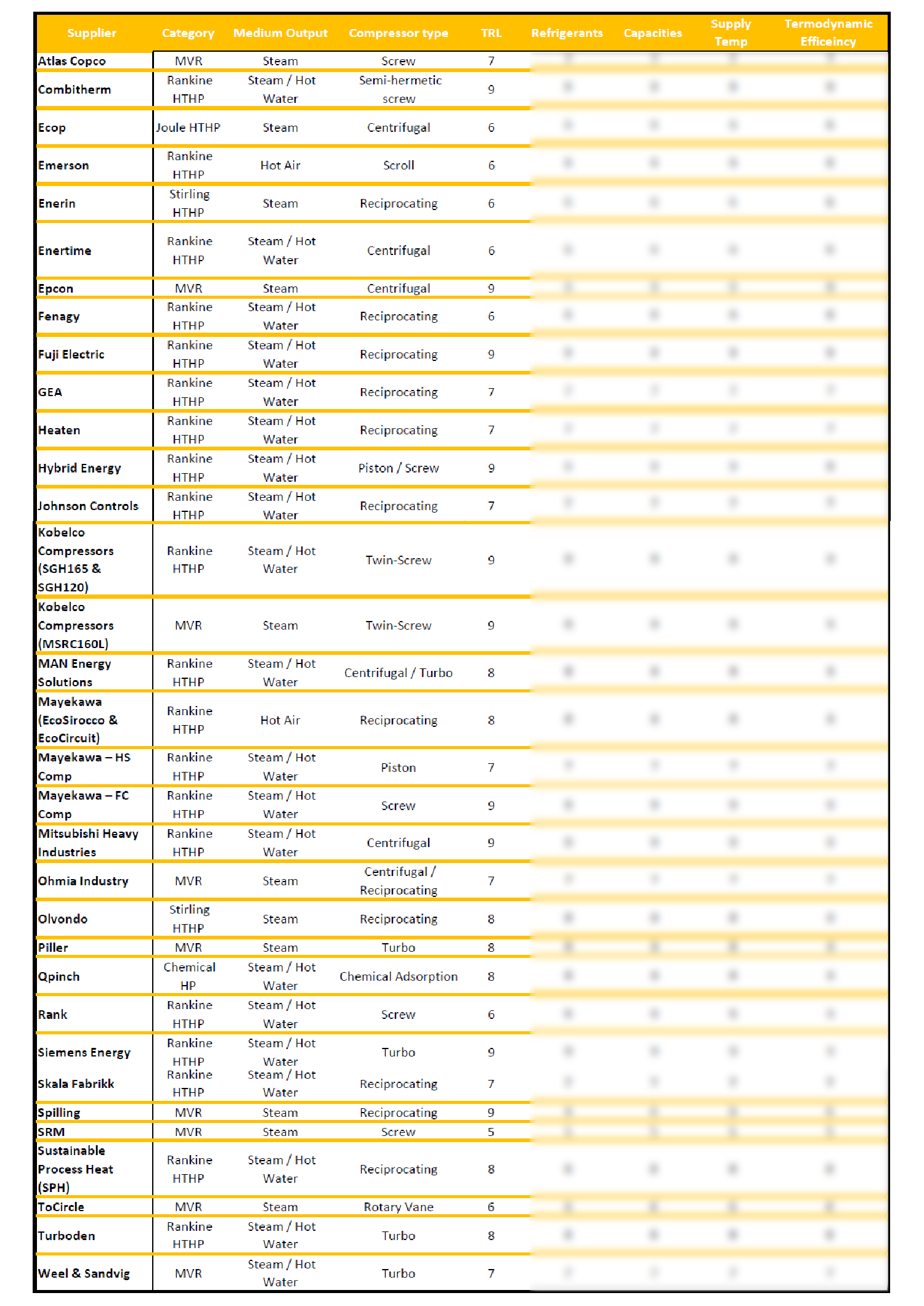

Next to the criteria mentioned above, additional criteria might be related to Thermodynamic Principle Category (E.g. Rankine Cycle, Stirling Cycle or Joule Cycle), Compressor Type (E.g. Reciprocating, Twin-screw, Piston or Centrifugal), Medium Output (Steam, Hot Air or Hot Water), Refrigerant, Capacity and Tmax supply. Below, 31 suppliers are classified in 2 groups: High Temperature Heat Pumps (HTHP) and Mechanical Vapor Recompression (MVR). Multiple options per supplier are shown.

When considering to make use of Heat Pumps to upgrade recovered waste heat, we are here to help. As we are independent from any supplier, we are happy to share all viable options. Our goal is for you to be informed and inspired by all the possibilities.

List of Industrial Heat Pump Suppliers

The Heat Pump technology suppliers mentioned in this table are based on Annex 58 created by the Danish Technological Institute (DTI). The DTI initially reviewed commercially available Heat Pump Systems, as well as systems under development.

Heat pump data

Would you like to know what HP would suit best with your site demands? Or would you like to receive more information on Refrigerants, Capacities, Supply Temperature, Thermodynamic Efficiency?

Request missing data of Heat Pump Table

What does an Industrial Heat Pump cost?

There are many factors that determine the price of industrial heat pumps. Even though the initial investment might be considerable, the possible benefits over-time may far outweigh the investment. As a rough estimate, we have encountered prices for industrial Heat Pumps ranging from €500.000,- towards €1.500.000,-. This price can vary significantly based on the following factors:

- System Size and Capacity: The size and capacity of the heat pump system depend on the amount of waste heat that needs to be upgraded. Larger systems with higher heat output capacities will generally come with higher upfront costs.

- Type of Heat Pump: The choice of heat pump technology, including whether it’s an air-source, water-source, or steam heat pump, can impact costs. Also the thermodynamical principle and compressor type may influence pricing.

- Refrigerant Choice: The selection of a refrigerant can also affect costs. Natural refrigerants like ammonia or carbon dioxide may have different cost profiles compared to synthetic refrigerants.

- Energy Efficiency: Investing in a more energy-efficient heat pump system with a higher Coefficient of Performance (COP) might have a higher initial cost but can result in greater long-term energy savings.

This price mentioned above is solely for the Heat Pump system. To ensure optimal performance, you should also consider related elements like:

- System Integration, Design & Engineering: By thinking through your process accordingly, you can save a lot of costs on the long term. A well designed System also reduces Maintenance and Operating costs.

- Installation and Integration: The installation process, including modifications to existing industrial processes to integrate the heat pump system, can contribute significantly to overall costs.

- Maintenance and Operating Costs: Consideration must be given to ongoing maintenance and operating costs, including electricity consumption, refrigerant management, and system upkeep.

- Heat Exchanger: A heat pump is useless without the right Heat Exchanger to effectively capture all waste heat.

To get an accurate cost estimate for an industrial heat pump project, it’s advisable to consult with an experienced system integrator who specializes in heat pump technology, like JOA. We can assess the specific needs of your industrial process and provide a detailed cost analysis based on your unique requirements.

While the initial investment in industrial heat pumps can be substantial, it’s important to view it as a long-term investment. Over time, the energy savings and potential reductions in emissions can lead to a return on investment (ROI) that makes the project financially attractive. Moreover, the positive environmental impact and alignment with Corporate Social Responsibility (CSR) and Sustainability Goals can provide additional value that goes beyond the financial aspect.

In conclusion, the cost of implementing an industrial heat pump system can vary widely based on multiple factors. Careful consideration of system size, technology choice, refrigerant, and operational costs is essential for making an informed decision about integrating heat pump technology into your industrial processes.

What suppliers of High Temperature Heat Pumps (HTHP) would JOA recommend?

Going through almost 40 suppliers worldwide of Heat Pumps providers, there are 2 that are able to also create steam at higher temperatures. These two suppliers of ‘High Temperature Heat Pumps’ (or HTHP) are: Sustainable Process Heat (SPH) and Mayakawa. ‘Rank’ is also promising but has a lower TRL level. Below, we will further introduce both parties:

SPH – Sustainable Process Heat

Based in Germany. Their ThermBooster HTHP produced by SPH, operates on a Rankine Cycle similar to typical industrial heat pumps. The use of advanced HFO refrigerants allows this heat pump to achieve high temperatures up to 160°C. The 4-cylinder piston compressor underwent recent optimizations resulting in significant pressure loss reduction. Also check their website: www.spheat.de

Mayekawa-Mycom

Thermal Engineering company headquartered in Japan. They offer a commercial example of a hydrocarbon heat pump for high temperatures. It uses natural refrigerants like n-pentane. Their High Temperatrure Heat Pumps have demonstrated to operate with pentane, which is less toxic than other natural refrigerants like ammonia. It’s global warming potential (GWP) is slightly higher, however. Visit website: www.mayekawa.com

Depending on your sites requirement and as developments continue, we might come with other preferred suppliers.