Why should you continuously gather data from your production process?

Polluted pipes in your process can be a real threat to productivity and explosion safety (ATEX). The downtime from maintenance can lead to many unwanted delays, let alone the impact it has on your operators and maintenance department.

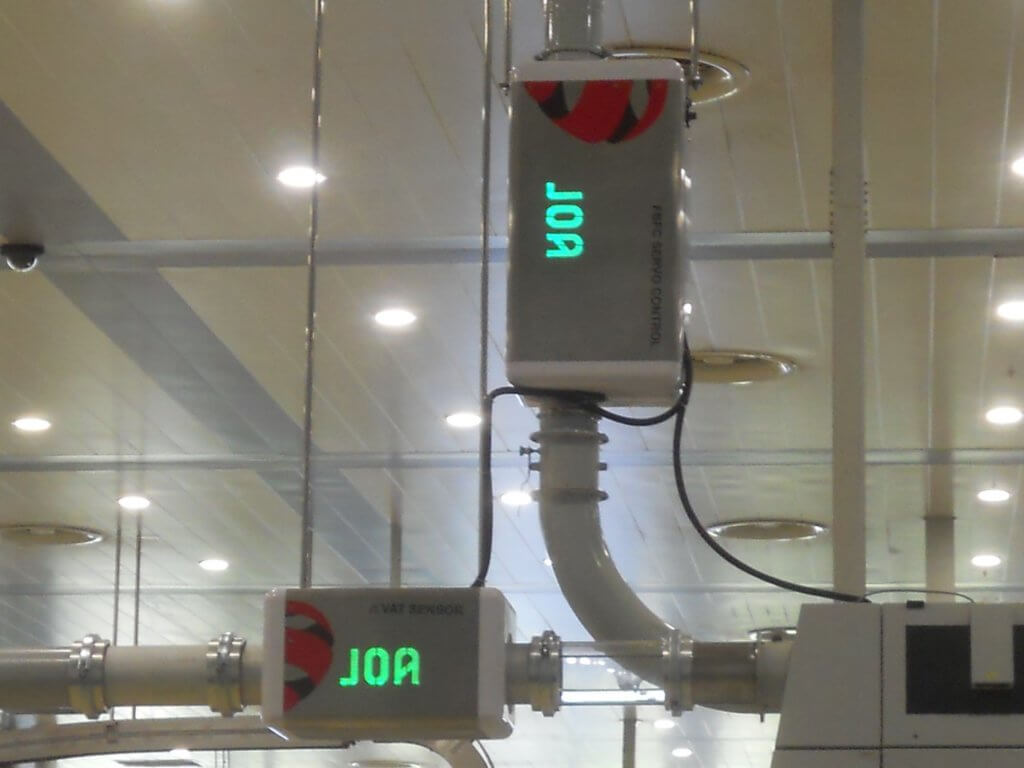

With JOA’s Air Flow Measurement Devices, you will be able to prevent pipe pollution and recognize additional improvements to your process. Normal pitot, measuring tubes, hot-wire or orifice measurements can often pollute relatively quickly, resulting in unreliable measurements.

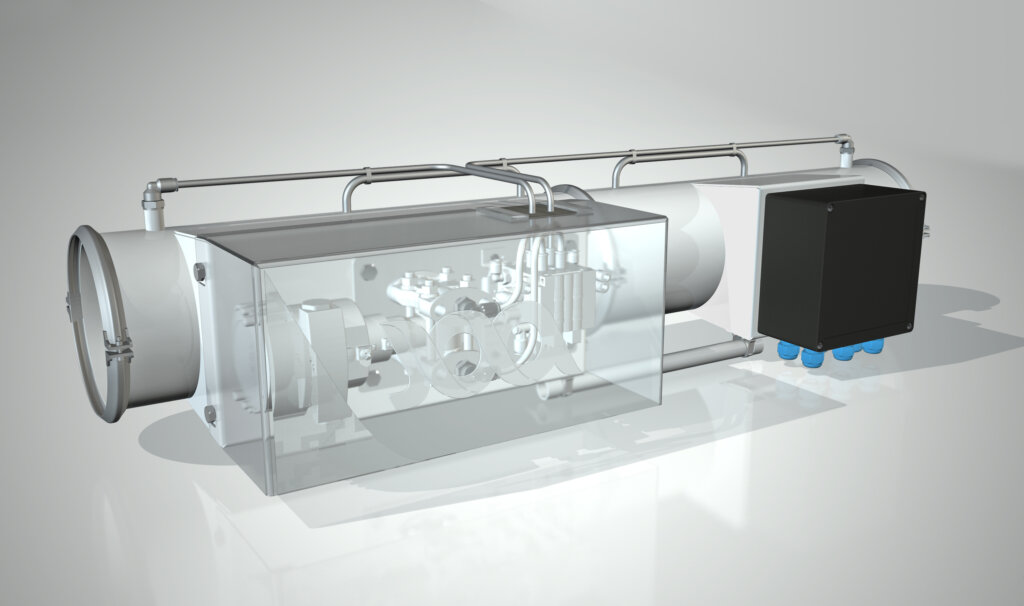

As our devices are designed for differential pressure measurement over a restriction, the pollution over a restriction causes much less pollution. Through the years, we have designed a better performing unique shape compared to an orifice plate.

How to measure the velocity or volume of Air and Gas

Easily put, Flow Measurement Units or ‘Flow Meters’ measure air or gas flows and volumes before and after an intervention. Installing multiple units per production line, also gives more information about process performance.

The measurement units have quick connections on both sides of the device to achieve easy inspections or replacements without intervening largely with your production process. This way, inspection hatches are not needed as well.

Flow Measurement Devices can go by many names like: Flow meters, flow instrumentation, flow indicator, flow rate sensor or flow gauge. This is all depending on industry, product and process.

Flow Measurement Equipment features and options

The flow measurement unit can be adapted and customized to your specific needs. We have two standardized units ready to be assembled.

The measurement equipment can be used for processes using both Air as Gas. The measuring tubes to the dP sensor are equipped with automatic compressed air purges that are periodically activated to avoid pollution in the measuring tubes. This ensures the accuracy of the measurements.

Additional features:

- ATEX Zone 22 compliant

- Able to operate as stand-alone device or with ‘smart connectivity’ features

- Cloud based storage to enable analysis assistance

Benefits of using Flow Measurement Units from JOA Air Solutions

- Exactly know what is happening in your production process in real time

- Prevent unreliable measurements

- Prevent pollution and clogging before it happens

- Know where to further upgrade your production process

- Unique design based on 22 years of experience within various industries and particle characteristics

- All devices can be adjusted to your site’s specific requirements

- Vast track record within the Ingredients, Sugar, Starch, Tobacco, Materials, Plastics and Pharmaceutical industries.

- JOA can assist with further data acquisition and analysis, making your site future proof