Start reducing waste and automate the conveying speed of your process with proven technology.

Take back control of your process and realize the highest output from your resources

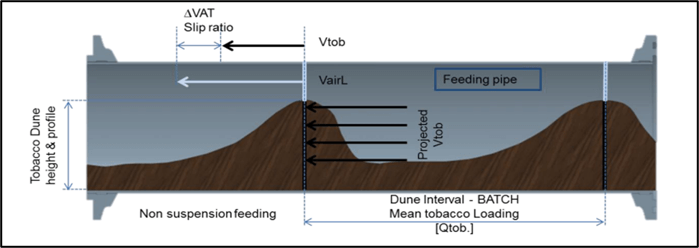

Speed and unequal distribution breaks down product during conveying. With JOA’s Air Conveying Control Unit, you will be able to:

- Automatically regulate product flow with smart sensors

- Lower velocities while conveying leading to less waste and product degradation

- Optimization of product conveying process

- Gain knowledge about product speeds, heights, static pressure and more

Is your product conveyed properly?

Based on thorough measurements and feeding system insights, you can get back control of your conveying process. With JOA’s Conveying Air Control Unit, you will be able to:

- Minimized loss of product while conveying

- Less wasted product and increased quality

- In control of conveying process, no fear of unpredicted stops

- Lower conveying velocities leading to lower energy usage

- Less downtime due to maintenance and cleaning

Taking the first steps in industrial conveying control

- On-site measurements & assessment of air flows

- Predict future outcomes and ROI based on Air Technical Modeling

- Install Conveying Air Control Unit

- Realize Yield Improvement immediately together with control of air flows & velocities

After installing over 200 units at more than 40 sites worldwide, we are able to achieve a waste reduction of between 0,8 and 1,9%

Start improving your conveying air velocities

We have an obligation to the planet to produce in an efficient way, next to realizing the most output from our resources.

- Yield improvement by minimized product degradation

- Robust proven design with proper feeding pipe sizes

- Optimal routing based on Air Technical Modelling

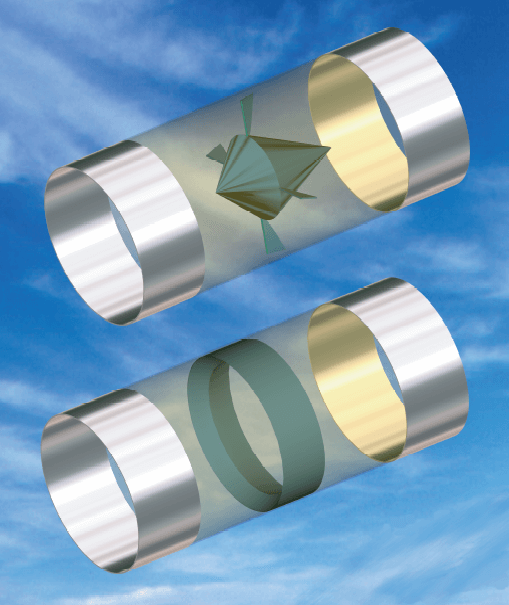

- Blend Selector flexible, extensible and compact design

- Product speed decrease resulting in less waste and energy needed

Industrial Conveying Air Control Features

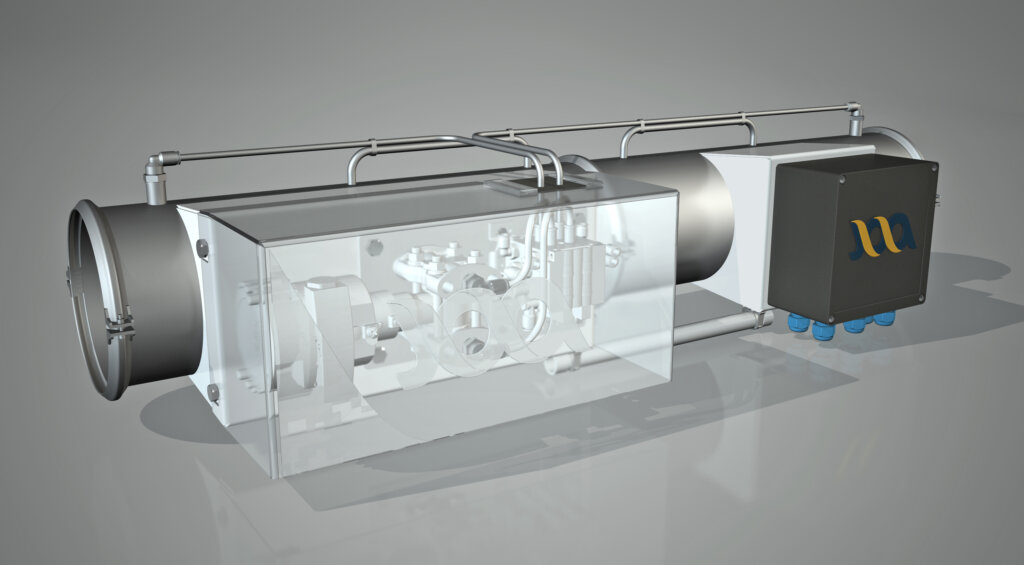

The Unit was developed in 2011 by our R&D department after seeing much product going to waste as uncontrolled transport leads to product wear. It’s robust design without footprint is easy to install and automatically creates optimal lowest velocities resulting in higher product quality and less waste. Additional features of the Conveying Air Control Unit are:

- Applicable for most pipe routings, including 125, 130 and 150 mm transport diameters

- Blend selector flexible, extensible and compact design

- Automatic monitoring and controls

- Valuable addition to you smart operations, fitting with Industry 4.0 strategy

- Air and Product (Tobacco) speed control within feeding pipe

Next to being able to quickly install an conveying control unit, JOA also provides maintenance service, onboarding, instruction manuals and remote support to make sure your process remains efficient at all times.

Before installing JOA Conveying Air Control Units, we faced product wear and regular downtime due to maintenance and cleaning. Now, I’m in control of my production process achieving higher product quality while consuming less energy

Tobacco Industry

Why work with JOA Air Solutions?

JOA chooses to take the time and effort to truly understand your site’s manufacturing process by collecting data and conduct on-site assessments. This way we truly learned to understand Air, Gasses and Pneumatic Conveying. Additional reasons to get in touch with JOA:

- We execute studies and predict future outcomes based on Air Technical Modelling

- We are trusted by the largest manufacturers worldwide. Withing the Tobacco industry, our Conveying Control Units are trusted by JTI, Philip Morris and ITC.

- Our designs are created and adjusted based on air flow measurements and modelling. This way we can advise on the optimal fan sizing, energy consumption and duct routing.

- Our systems are built in the Netherlands to guarantee quality

- Our systems are IoT ready and can be outfitted with real-time monitoring & control.

Share your challenge and start improving your conveying process!

Production Process Control with various conveyed products

JOA has successfully installed more than 200 Conveying Control Units at more than 40 production sites worldwide. Most experience is gained in the Tobacco industry as loose fibers have the highest possible friction. By transporting at lower speeds with bundles of tobacco, only the outside of the bundle faces friction. Additional conveyed products may include:

- Tea leafs

- Coffee beans

- Nuts

- Seeds

- Grains / Wheat / Cereals

- Hop