What is a Scrubber

Scrubbers are air pollution control equipment that washes away dust, vapors or gasses coming out at the end of a production process. The achieved result is a clean and efficient process which is most commonly realized by using water.

The scrubbing principle relies on effective atomizing and contacting of the scrubbing reagent with the exhaust stream to attach particles, dissolve or adsorb aerosols and vapors in the reagents or to initiate a chemical reaction. The contaminated reagent is separated from the exhaust stream in the (integrated) mist eliminator from where the reagent is filtered and reused in the process, minimizing water and chemicals consumption.

JOA Exhaust Air Treatment Solutions

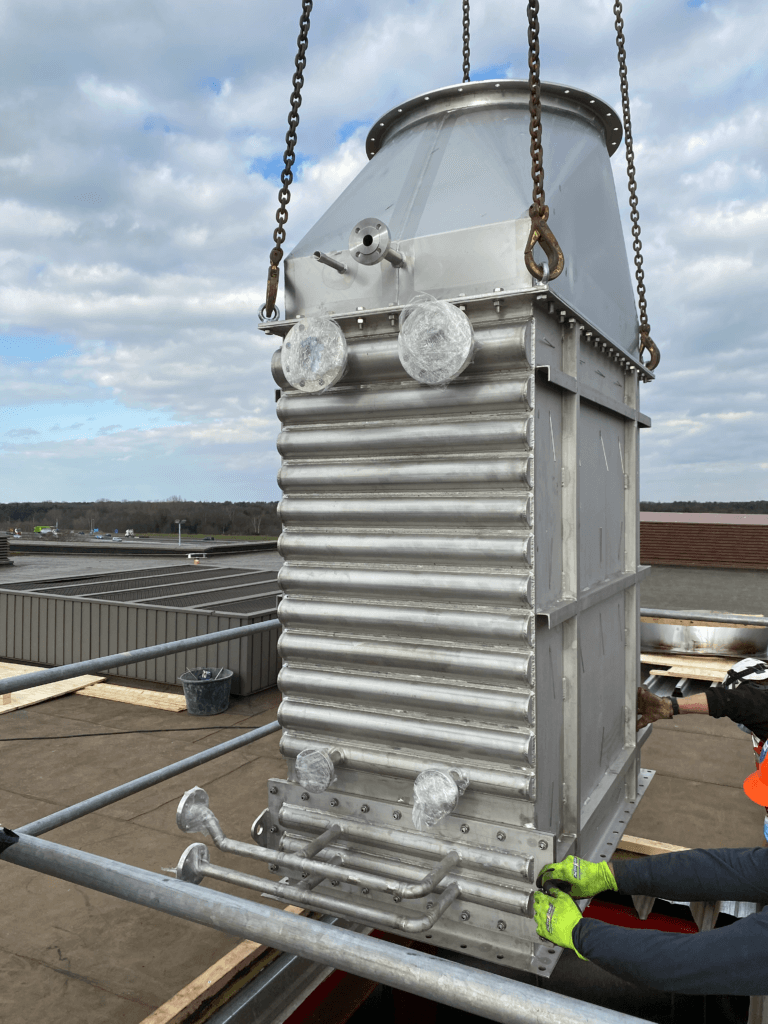

In-line Venturi Scrubber

Often used for medium and high fume concentrations. The in-line Venturi Scrubber is especially efficient for processes producing solidifying fumes or combinations of fumes and dust. JOA provides a wide range of standardized In-line Venturi Scrubbers. The scrubbers are designed for low energy- and water/reagent consumption and can be equipped with BIO fouling control.

For combined fume and dust collection. The most complicated fume extraction systems are those which involve processes with both fumes and dust. In some processes dust particles form out of the extracted fumes (e.g. solidification of waxes). For these processes it is best to apply a wet (inline venturi) dust scrubber rather than a dry filtration solution.

Packed Bed Column

A packed bed is a hollow tube, pipe, or other vessel that is filled with packing material. The packing can be randomly filled with small objects like ‘Raschig Rings’ or specifically designed with structured packing.

Packed bed columns are largely used for absorption, desorption, rectification and direct heat transfer processes in the Chemical and Food industries. They are also used for Environmental Protection and processes in thermal power stations like water purification, flue gas heat utilization and SO2 removal.

These separation processes, are estimated to account for 40%-70% of capital and operating costs in the Process Industry. The usage of Packed Bed Columns for direct heat transfer between gas and liquids, enlarge their importance. They are the best apparatuses, from thermodynamical point of view, for mass and heat transfer processes between gas and liquid phase.