JOA’s Balancing Restrictors prevent fouling of the pipe, extend operation before cleaning is required and takes care of an optimal flow profile after bends and inflow parts in the piping network. Furthermore, it is able to Balance large (>50 points) extraction systems on 1Pa precise.

Why are Balancing Restrictors needed for effective extraction?

Balancing Restrictors will achieve an ideal air flow and improve the performance of a production process. Plugged filters or even changing weather patterns can affect the airflow in your dust collection system. In a facility with a ventilation system having multiple pickup points on a single-fan system, each of those points may need adjustment to provide adequate airflow.

Your system’s air velocity needs to exactly match the range required for the particulates you are capturing:

- Too high of air velocity may decrease filter life; erode the ductwork; coat duct walls with dust in the case of moist or sticky particulates; and waste energy.

- Too low of air velocity may cause dust to drop and build up in the ductwork. This may cause dirty workplaces, more downtime due to maintenance and explosion risk.

How does a Balancing Restrictor work?

Achieving optimum Air Flow through an industrial dust collection or vapor extraction system is done by creating balance in the system. Balancing involves adjusting dampers to provide proper Air Flow to individual pickup points. It’s important here to understand exactly how your industrial dust collection system is performing and how to accommodate the ever-changing effects on the system through balancing. In combination with JOA’s GCM™ Air Technical Modeling software, the correct positions of these pressure and velocity controllers are calculated.

Dampers ensure the fan is pulling the right air volume needed, so that adjusting the dampers creates resistance. By creating this resistance, it’s easier to pull air from the different branches of the system.

What are Balancing Restrictors

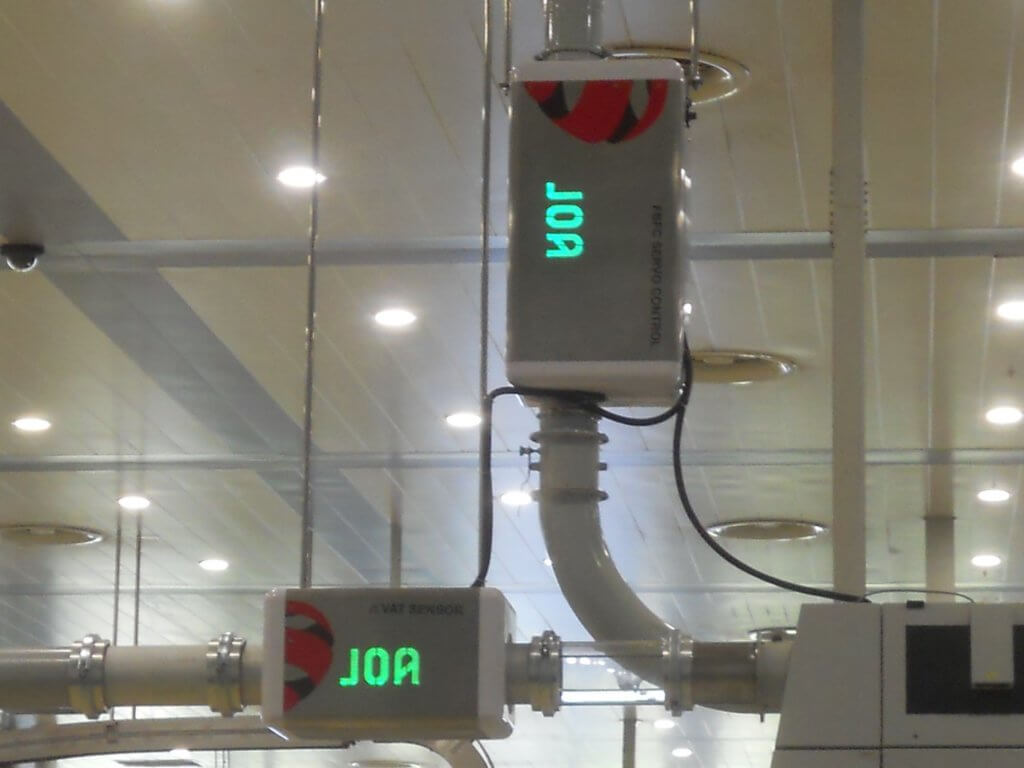

The JOA® patented Restrictor™ acts as a static mixer, distributing and entraining the dust/vapor through the pipe diameter, preventing system fouling. Furthermore it provides pressure control to ensure a balanced system design.

JOA balancing restrictors guarantee a stable process and prevent over-extraction and loss of valuable powders. Special de-gritter and deflector hood designs recover valuable products at the extraction point, reaching yield improvement up to 40-45%.

JOA BALANCING RESTRICTORS BENEFITS:

- Precise pressure balancing

- Unnecessary adjustments are avoided

- Optimal dust entrainment (Duplex)

- Long-term system stability