JOA Air Solutions introduces Air Technical Modeling , a state-of-the-art and patented technology designed by JOA to identify bottlenecks and validate designs of emission control systems and energy recovery equipment. Our solution offers comprehensive modeling for dedusting and vapor extraction systems, ensuring stability, reliability, and efficiency for industrial manufacturing companies across Europe.

Why is Air Technical Modeling Important?

Air Technical Modeling plays a pivotal role in the planning and creation of complex industrial extraction systems.

Contact usStability and Efficiency

Ensures systems operate reliably without the risk of failure or inefficiency, which is crucial in maintaining a clean and safe work environment.

Precision and Optimization

Models every component of the system (from ducts to filters) to optimal specifications, minimizing resource waste and operational costs.

Predictive Performance & Process Guarantees

Predicts how the system will behave, reducing the likelihood of unexpected setbacks and enabling systems to function correctly from the moment they are commissioned. It gives JOA the opportunity to provide Process Guarantees on the performance of the proposed solution.

Main Pain Points of Standard Filtration Suppliers

- In many cases, standard equipment works totally fine. We believe that when industrial processes become larger and more complex, a tailor-made solution becomes a necessity. The main issues related to Standard Equipment Suppliers are:

- Over-extraction

- Under-extraction

- Cross contamination

- Wasting resources

- Higher Energy Costs

- Trial & Error after commissioning

- Higher Maintenance costs

- Risk of downtime due to unpredicted clogging, cleaning, maintenance

At JOA, we ensure that every system is designed, built, and implemented to meet the highest standards and your specific needs. From initial design through to final commissioning, our expert team manages every detail with precision. Experience the benefit of having all services from consultancy to commissioning under one roof.

What is Air Technical Modeling?

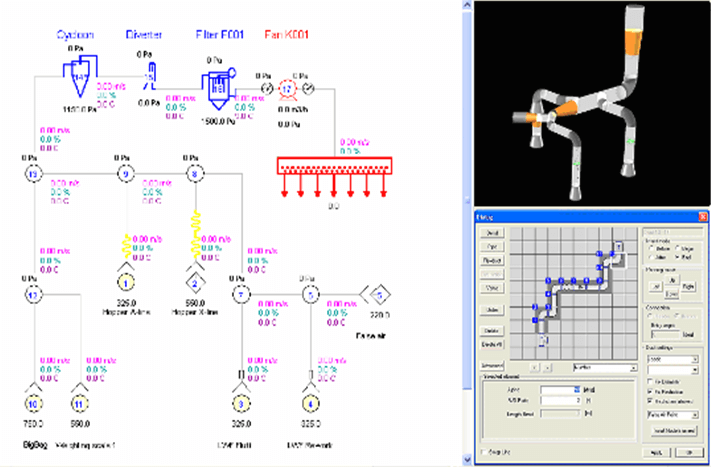

Modeling, particularly in air technical simulations, is a critical process used to design, optimize, and ensure the efficiency of industrial dust collection and vapor extraction systems. By using advanced simulation software, we can predict and enhance the system’s performance, making installations more effective and reducing the need for post-implementation adjustments. Internally the Air Technical Modeling software is called ‘GCM’ (Graphical Computational Modeling) as it calculates and visualizes air flows.

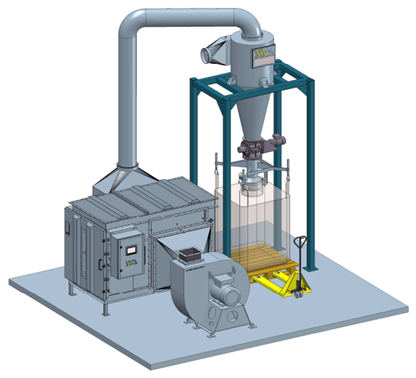

Air Technical Modeling is a comprehensive, data-driven solution designed to simulate and validate designs for industrial dust and vapor extraction systems. It uses a combination of calculations, factory measurements, and pre-engineering inputs to generate accurate simulations. Examples of elements that may be included in the modeling software during the Pre-Engineering phase may include:

- Extraction capabilities

- Optimal Duct Routings

- Equipment layout

- Temperatures and Relative Humidity

- Equipment like filters, scrubbers, cyclones, valves, fans, hoods, heaters, chillers, carousels and piping.

By using Air Technical Modeling, we are able to provide better concept designs and a high reliability on future performance of our systems. The ‘Proven Process’ we follow allows for balanced, stable, and efficient systems that minimize risks and unexpected setbacks during realization and operation.

No operator likes to work in a dusty environment

How Air Technical Modeling Benefits Your Extraction Systems:

- Pre-Engineering Insights: Data-driven modeling, lab results, and factory measurements contribute to the design of economic, long-lasting systems with a meaningful process guarantee. Modeling is an important part of Pre-Engineering Studies where advanced calculations (Flow rate, temperature, energy recovery potential, etc.) are combined with a thorough advice, concept design and budget quotation.

- Scenario Management: The software allows for scenario management, preventing overdesign and minimizing fluctuations, resulting in stable extraction systems. The software integrates detailed data from the pre-engineering phase to model the entire extraction system.

- Visualization and Automation: Offers sophisticated visualization options that help in understanding system dynamics and automating design requirements for precise implementation. It helps showing capacity and pressure of fan requirements, plot velocities (together with CFD Modeling), capacities and temperatures and quickly shows system requirements.

- Performance from Commissioning: Our solutions eliminate the need for post-commissioning optimization, reducing downtime, maintenance and cleaning intervals. It prevents trial & error and ensures balanced extraction systems from the start.

Balanced Extraction Systems leads to Healthy Work Environments, Explosion Safety and smooth operations

JOA Air Solutions recognizes the importance of stable, reliable extraction systems for both operational efficiency and workplace safety. Dust and vapor emissions pose health hazards to operators and increase the risk of corrosion and downtime. By using Air Technical Modeling, efficient and balanced extraction systems can be designed, addressing these challenges comprehensively.

Why Choose JOA Air Solutions?

Since 1998, JOA Air Solutions has been at the forefront of the Food Production, Consumer Goods, and Chemical industries, developing and applying Air Technical Modeling to design non-polluting extraction systems. Our expertise includes:

- Dust Collection Systems

- Vapor & Fume Extraction Systems

- Heat Pump & Heat Exchanger Integration

- Explosion Safety

- Healthy Work Environments

Benefits of using Air Technical Modeling

- Comprehensive Modeling: We provide detailed simulations considering extraction capacities, duct routings, and equipment placement.

- Advanced Settings: Our software can simulate temperature and humidity throughout the system, account for equipment like filters and scrubbers, and manage advanced piping lists.

- Visualization & Automation: We offer advanced plotting for velocities, capacities, and temperatures, along with quick, automated system requirements. It helps further understanding of particulate matter behavior.

- Reduced Risk, Costs and Downtime: Accurate modeling minimizes the risk of operational failures and downtime by ensuring the system is built to precise specifications. Optimal system design reduces unnecessary expenditure on energy and maintenance. It also minimizes risks and unexpected setbacks during System Realization.

- Compliance and Safety: Meet industry standards and regulations, ensuring a safe environment for operators and minimizing environmental impact.

Modeling makes the difference between knowing what to expect and hoping for the best

René Bosscher, Sr. Consultant Service & Modeling

Contact Us Today!

If your operation needs optimized and balanced extraction systems, contact us today to learn how JOA Air Solutions can make the difference between knowing what to expect and hoping for the best.

FAQ

Q. Can I make use of your Air Technical Modeling tool myself?

A. Unfortunately, we do not allow access to this technology. This in-house developed software is crucial for our operations. Also, it only works well in combination with measurements, experienced engineers and a thorough understanding of your process in combination with knowledge of emission control.

Q. How is Air Technical Modeling related to your other services?

A. The start of almost every challenge that we face, begins with a Pre-Engineering Study. During this study, we gather data and take measurements. This is input for Air Technical Modeling that will identify bottlenecks and opportunities for improvement. Next to the early phase, we use Air Technical to validate the concept design proposed in the Pre-Engineering Study and during the Design & Engineering phase afterwards.

Q. How does Air Technical Modeling benefit industrial manufacturing companies?

A. Air Technical Modeling offers multiple benefits for industrial manufacturing companies, including:

– Accurate simulations: Ensuring balanced and efficient extraction systems.

– Scenario management: Allowing various configurations to be tested, preventing overdesign and ensuring optimal equipment setups.

– Comprehensive visualization: Providing detailed plots for each section of the system, including velocities, capacities, and temperatures, along with piping lists and equipment placements.

– Time and cost efficiency: Ensuring first-time right implementation, reducing downtime, maintenance intervals, and cleaning costs.

Q. What industries benefit the most from Air Technical Modeling?

A. Air Technical Modeling is particularly beneficial for industries such as Food Production, Consumer Goods, and Chemicals. In these industries, dust and vapor extraction systems are crucial for both operational efficiency and workplace safety. The modeling ensures balanced extraction systems that minimize health risks, improve process reliability, and prevent downtime due to equipment failure or pollution buildup.

Q. How does Air Technical Modeling help with long-term system reliability?

Air Technical Modeling ensures long-term reliability by:

– Providing precise designs: Which are based on comprehensive data, ensuring balanced extraction systems from commissioning.

– Minimizing post-commissioning optimization: By ensuring systems are designed “first-time right,” reducing the need for downtime and maintenance.

– Predicting future scenarios: Through scenario management, allowing for adjustments to meet changing operational needs, further reducing maintenance and cleaning intervals.Q. How does Air Technical Modeling integrate with existing systems?

Air Technical Modeling integrates seamlessly with existing systems by providing advanced piping lists, equipment setups, and comprehensive visualizations. The modeling software allows for detailed simulations and design adjustments, ensuring that the new or modified extraction systems are compatible with existing setups, minimizing operational disruptions. Additionally, the system provides detailed plots for each section, allowing engineers to ensure effective integration.