Main challenges of Manufacturers in the Food, Feed, Pharma and Chemical Industries:

-

ATEX Compliance

-

Downtime & Maintenance (See Service)

-

Cleaning in place (See Acoustic Agglomeration)

-

Reduce Emissions and emission control

-

Risk Reduction (See GCM Modeling)

-

CSR Goals, Environmental Sustainability

-

Energy Reduction

-

Operator Safety Regulations

-

Limited time for New system implementation/upgrades during plant stop (See Realization)

Risks of handling dust

-

Explosivity

80% of the dust filtration systems have fire and explosive risks. This is why dust filter systems should be designed in a more balanced way.

-

Wastewater stream

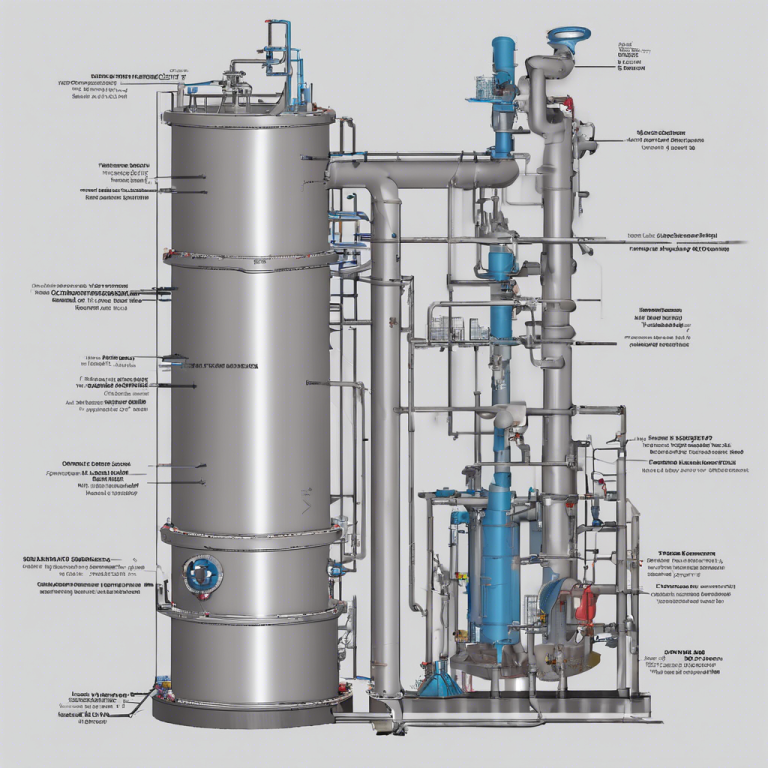

A combination of particles and vapor can be removed by a wet scrubber, rather than a dry dust filter. However, treatment the wastewater stream produced by the scrubber is sometimes neglected.

-

ATEX Regulations

Combustible dust standards to prevent injury and property loss due to fire hazards.

Create a Healthy Work Environment

There is nothing more important than being able to work in a healthy environment. According to the World Health Organization, air pollution has been linked to a range of negative health effects. This includes cardiovascular and lung diseases. Indoor exposure to air pollutants is a serious long-term health risk for your operators. Therefore, it is a necessity to address this professionally by creating a healthy work environment.

How to increase Explosion Safety?

Protecting your operators and assets from explosions deserves the attention of every QHSE officer and Plant Manager. Only implementing ATEX compliant equipment and standard dedusting systems will not suffice. JOA’s approach includes truly understanding your site’s requirements, predictive air technical modeling and tailor-made engineering integrating proven equipment to create safe operations protecting your operators and assets.

How to reduce and recover energy?

Every production plant is looking for ways to reduce and recover energy. A good example where we achieved this is a project for an ammonium sulphate fertilizer plant. By utilizing JOA inline venturi scrubber effluent as process make-up water, the wet-scrubbing systems can deliver both environmental as economic benefits. Another benefit is direct energy recovery, using the exhaust air from driers and flash towers to recover the energy for direct steam or hot water generation. As a result, the energy recovery efficiency ranged from 70% to 85%.

Controlling Air Emission Limits and Legislation

It is essential for your factory to comply with emission limits on dust, vapor, and Odor. Choosing the right technology will make this simpler while also notably improving energy efficiency. In over 1000 executed projects, JOA has made an impact reducing waste-water streams. Therefore, we prefer “dry” filter techniques over wet scrubbers. We only advise wet scrubbers when the effluent waste-water stream can be recycled effectively into the production process.

How to improve operational expenses in industrial processes?

JOA’s extraction system guarantees a balanced process and a healthy and safe work environment that complies with relevant standards. Moreover, we deliver economic benefits through improved processes stability and product quality.

Our systems are designed base on air technical modeling software with which we have applied distributed conveying velocities to control dust and vapor build-up. Additionally, we use CFD-optimized extraction hoods and enclosures. This minimizes the extraction of valuable dust and protects manufactured products. At the same time, it reduces the downtime of the facility because the factory needs less cleaning or dust filter replacement.