Understanding particles and the forces that apply to them

JOA is a worldwide leader in truly understand particles. We love to analyze them and figure out solutions to fluently run them through your manufacturing process.

Create value by accurate modeling and understanding particles

Rene Bosscher, Chief Modeling & Service

Data-driven modeling based on lab results and site measurements contributes to building economical and reliable, long lasting extraction systems.

How to create better designed extraction systems with Force Balance modeling

JOA has a vast track record in researching and getting to understand particles.

Proven process to improve manufacturing processes:

- Introduction meeting: Sharing industrial challenge

- Site Survey, taking measurements and collecting data

- Particle Force Balance Modeling and/or Air Technical Modeling

- Report back findings, including possible opportunities for improvement (including quotes)

- Optional:

- Design & Engineering of upgrade

- Building upgraded or new Extraction Systems

- Planning Implementation

- Service, Maintenance and Spare Parts

How to truly understand particle characteristics

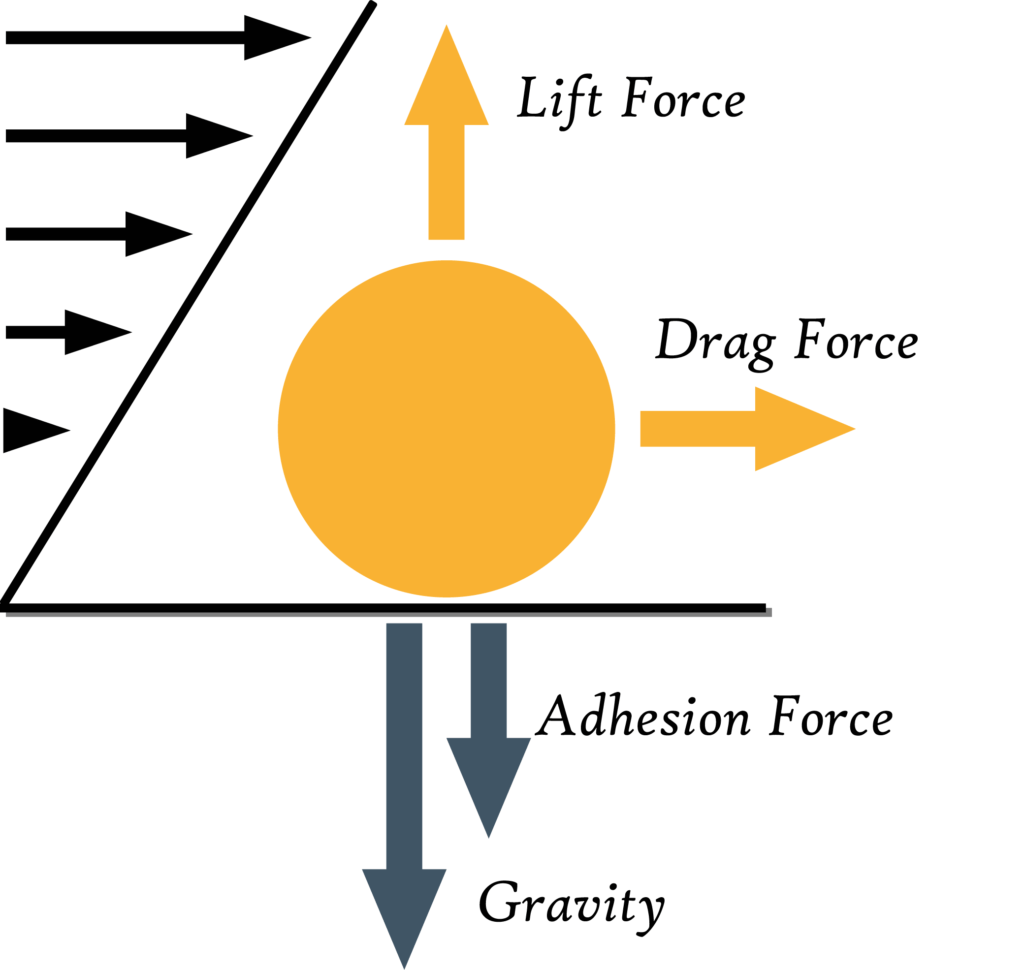

There are four different forces influencing particles in industrial processes:

- Adhesion: Keeps particles attached to a surface. Relatively strong force for small particles. However, this can vary widely (orders of magnitude) due to relative humidity, kind of material, and processing history.

- Gravity: The easiest force to calculate once the particle density is known. It is a straightforward measurement and calculation. Often keeps the particles attached to a surface.

- Lift and drag: Forces that try to remove particles from the surface. Both are directly related to the average flow velocity and size of the particle. There are different models with different coefficients that depend on the flow regime (laminar, turbulent, transition) for the lift and drag coefficients.

If a particle starts rolling, it is much easier for the lift force to remove the particle from the surface. Also, due to the rolling action the magnus effect can generate additional lift on the particle. The critical velocity for particle detachment is found by balancing all the forces on the particle.

Adhesion + Gravitational Force = Lift force + Drag

All the forces have different impacts on the particle transport and are also functions of different parameters, which makes modeling more tedious. Analyzing the different forces on the particle in combination with different flow regimes is necessary. A wide variety of transport phenomena can be observed:

- Rolling

- Direct lift-off

- Sliding

All have a big impact on the fouling risk of piping by transporting (conveying) dust and aerosols to the filter unit. Understanding the different forces on the particles in combination with knowledge of the boundary layers, the flow events in these layers (turbulent burst or streaks), and the experimental measurements are essential for understanding overall dust conveying.

Minimal fouling particle modeling can double the cleaning interval of your piping network

Sarfraz Ghani, Chief Engineer E&I

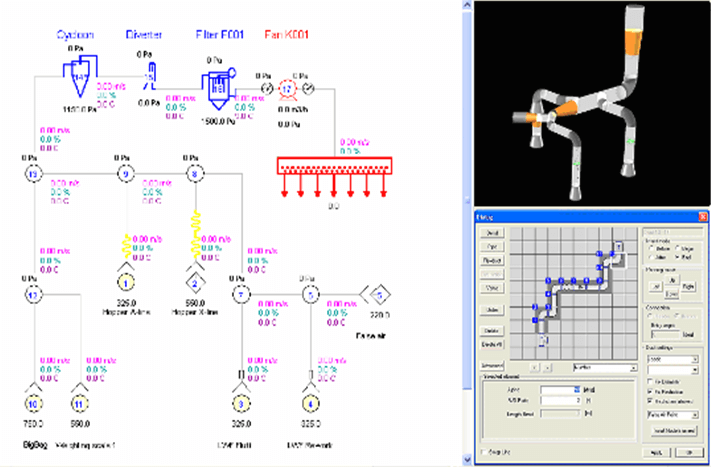

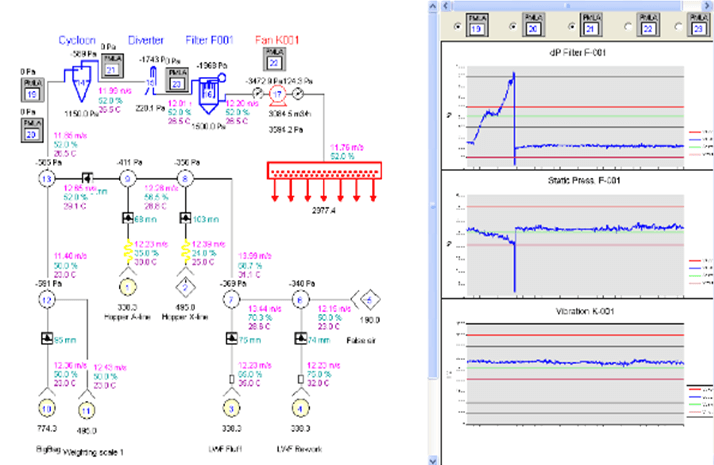

JOA Force Balancing & Air Technical Modeling software

Dust emission samples are analyzed to determine the minimal velocity required for maximum re-entrainment of particles into the pipe core. The particle data is entered into our dynamic software in order to compute the velocity profile of the material to be extracted. This software was developed with the cooperation of the Technical University of Delft. This unique model calculates all the forces present on air borne particulate, vapor and fumes that are being conveyed in an extraction system. Our Force balancing model calculates the optimum conveyance velocity, minimizing risk for material settlement or duct fouling.

The air technical modeling tool, developed by JOA, helps to design, visualize, and balance extraction systems for both dust and vapor. This Air Technical Model operates on an iterative basis resulting in precise system balancing, including velocity and static pressure. Air technical modeling will ensure that all equipment meets expected requirements and provide a basis for insuring optimum dust control, system stability, and long-term system performance.

JOA Air Technical Modeling, combined with optimal conveying velocity, resulting in required system balance and guaranteed process uptime.

Benefits of creating a deep understanding of particles before designing dust & vapor extraction upgrades

- Prevent trial and error iterations by accurate predictions of pressure drops

- Gain knowledge of particle fluid interaction

- Improve and debottlenecking existing systems

- Deliver optimal designs for new extraction systems, implemented the first time right

- Prevention of condensation related fouling by placement of make-up air units resulting in optimized energy usage

- Precisely balanced, controlled and stable extraction systems

- Stable operations of key production equipment

- Predictive modeling provides process guarantees

- Less maintenance needed and an increase in cleaning intervals

- Minimized product loss and fouling

- Extraction on demand (carrousel)