Prevent pipe pollution, reduce downtime and increase explosion safety of your industrial operations.

What is flow rate and why should you measure it?

Flow rate is the volume of fluid (Product, Air and/or Gas) that passes per unit of time. It is also known as volume flow rate, volumetric flow rate or volume velocity. If a pipeline is polluted, the flow rate will become lower than usual. That’s why measuring flow rate is a great way to detect pollution at an early stage and reduce the risk of explosion.

Polluted pipes can cause significant problems

Unpredicted downtime never comes at a convenient moment. The downtime from unexpected maintenance can lead to unwanted delays and significant losses in profit. But even planned maintenance isn’t ideal. Every minute your process isn’t running, money is lost, so you want to reduce maintenance to a minimum. Measuring flow rate can help you achieve this, by collecting data and by predicting the reach of the lower limit.

JOA can help you truly understand your processes, their limits and the possible improvements by doing a site survey, including measurements.

Risk of explosion

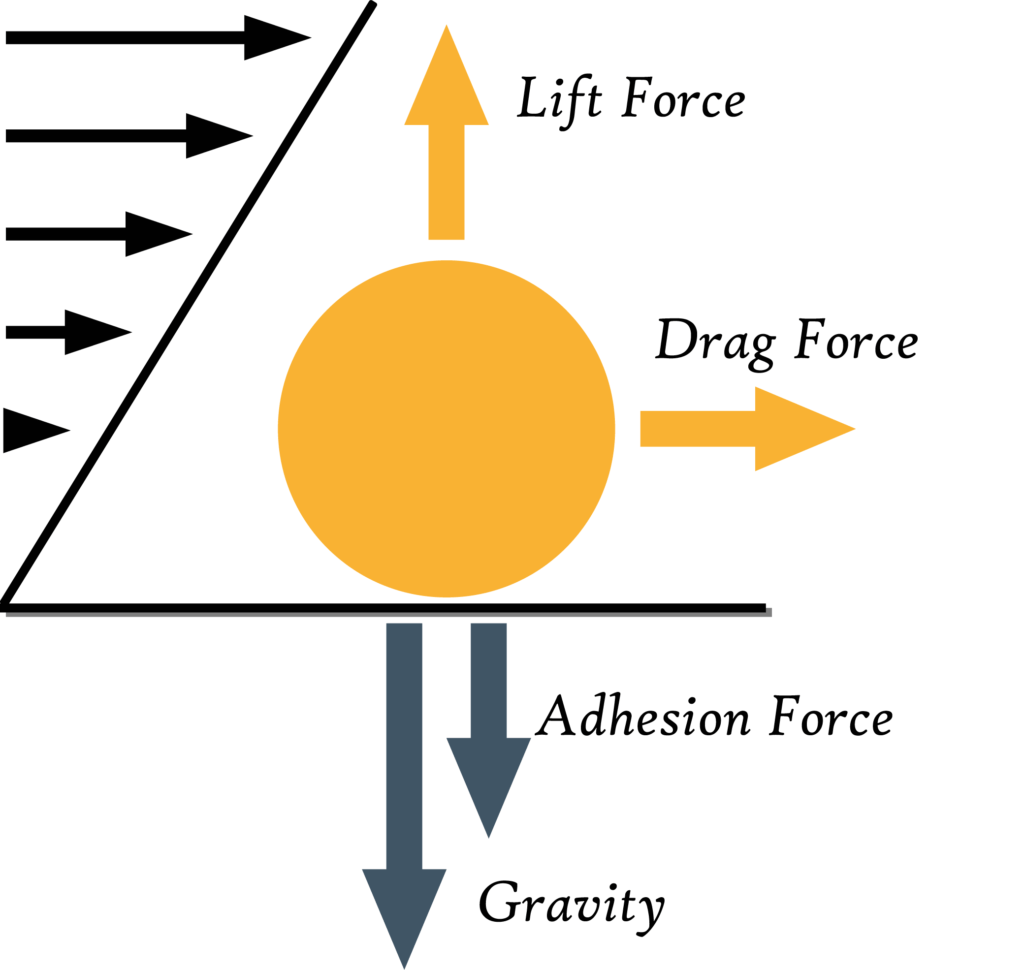

Polluted pipes can create significant hazards:

- Clogging provides a risk at the extraction point.

- Dust in its purest form as a static layer, in or on a pipe, is a fire hazard.

- Dust in the right ratio with air causes an explosion hazard.

Therefore, transported dust needs to be monitored closely.

Cross-contamination

You may transport different (batches of) materials through the same pipe. Pipe clogging can cause the previous material to get stuck, which could cause unwanted cross-contamination. By preventing pipes from clogging, you will also reduce the risk of cross-contamination. Nobody likes the taste of garlic in their vanilla milkshake.

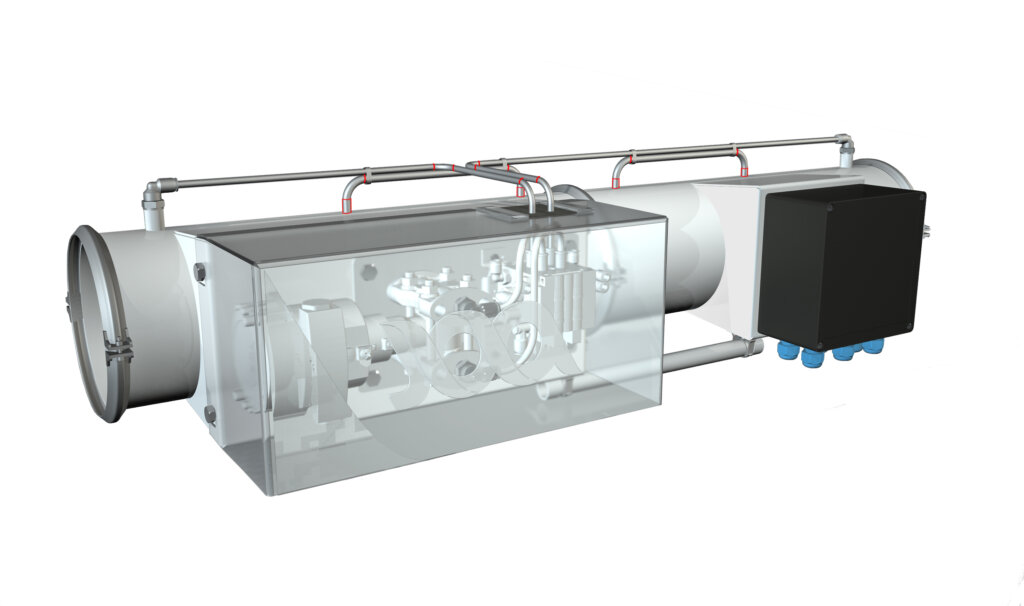

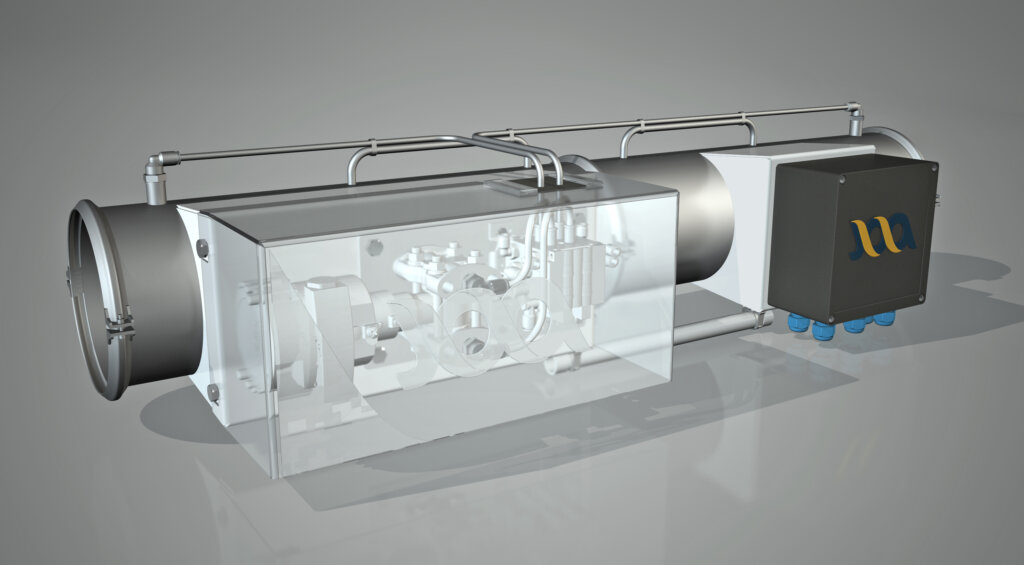

What is an Air Flow Measurement Unit?

Easily put, Air Flow Measurement Units or ‘Flow Meters’ measure air or gas flows and volumes before and after an intervention. Flow Measurement Devices can go by many names, like flow meter, flow instrumentation, flow indicator, flow rate sensor, or flow gauge. This depends on the industry, product, and process. At JOA, we call them ‘Air Flow Measurement Units’.

Many flow measurement methods are failing

Many flow measurement methods, like Hydraulic Turbines and Pitot Tubes, are failing. These methods are commonly used, but know considerable downsides:

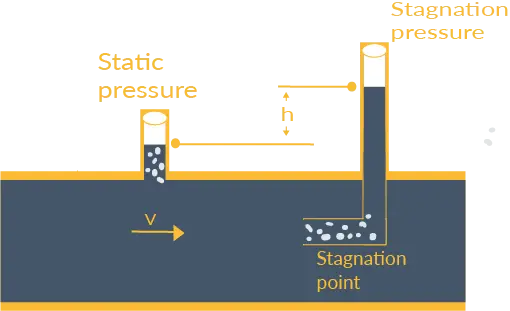

Downsides of using Pitot tubes

This method is very accurate, but Pitot tubes catch a lot of dust. Therefore they need a lot of maintenance. The measurements become less accurate when they take longer due to clogging. Pitot tubes also need a minimum airspeed to measure accurately. This could mean that a pitot tube does not work for your current system.

Downsides of using Turbine Anemometer

Turbine Anemometers enable accurate measurements, because flow rate can be calculated linearly using orbital velocity. Static loads are possible. But these units can create sparks, which could cause explosions. They are also sensitive to dust (but not as sensitive as pitot tubes because dust will fall off).

Downsides of using Aneroid gauges / mechanical gauges

These work by hanging a weight on a stick and by using the surface size and calculated deflection of the stick. More deflection means more flow. This is a very simple and robust method but also has its downsides. Before you use this method, the measurement range needs to be very clear. It isn’t precise enough to measure a difference at a high flow rate and when it’s outside of the measurement range it cannot be used.

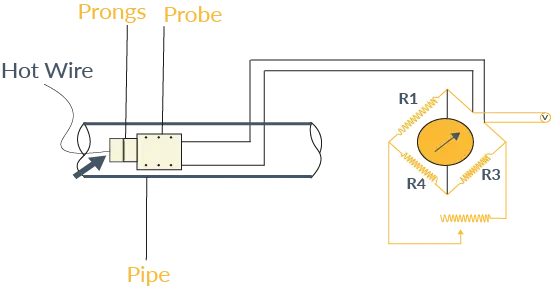

Downsides of using a Hot Wire Anemometer

This method generally works quite well, but it adds a lot of heat to your system and can cause sparks. Therefore it cannot be used with dust and other flammable or explosive substances.

Industrial thermal mass flow meters (insertion type)

Similar to hot wire technology, thermal mass flow meters are used in many industrial applications. However they can be sensitive to dust/ dirt which may eventually build up on the sensor element (fouling). This can result in signal drift over time. For auxiliary processes around filter installations, for example compressed air flow measurement, VPInstruments in Delft provides a range of thermal mass flow meters. These instruments help in monitoring the total air consumption of bag filter houses, offering a proactive approach to preventing expensive leakages or failures in the regeneration process.

A new and improved way to measure air flow in industrial processes

JOA created a new and improved way to measure air flow, without the downsides of the solutions mentioned earlier. This is how it works:

During manufacturing processes waste dust is emitted or conveyed. Our unit is attached to the extractor, in the middle of the piping, and measures the conveyed air. When too little powder or dust is being conveyed you’ll know something is wrong. That is a sign of pollution and clogging. Adding one or multiple units to your production line will enable you to detect pollution at an early stage and solve problems before they become a real threat to productivity or safety.

Our Air Flow Measurement Units have a lot of advantages compared to other solutions:

Automatic prevention of pollution and clogging

Normal pitot, measuring tube, hot-wire, or orifice measurements will often pollute relatively quickly, resulting in unreliable measurements.

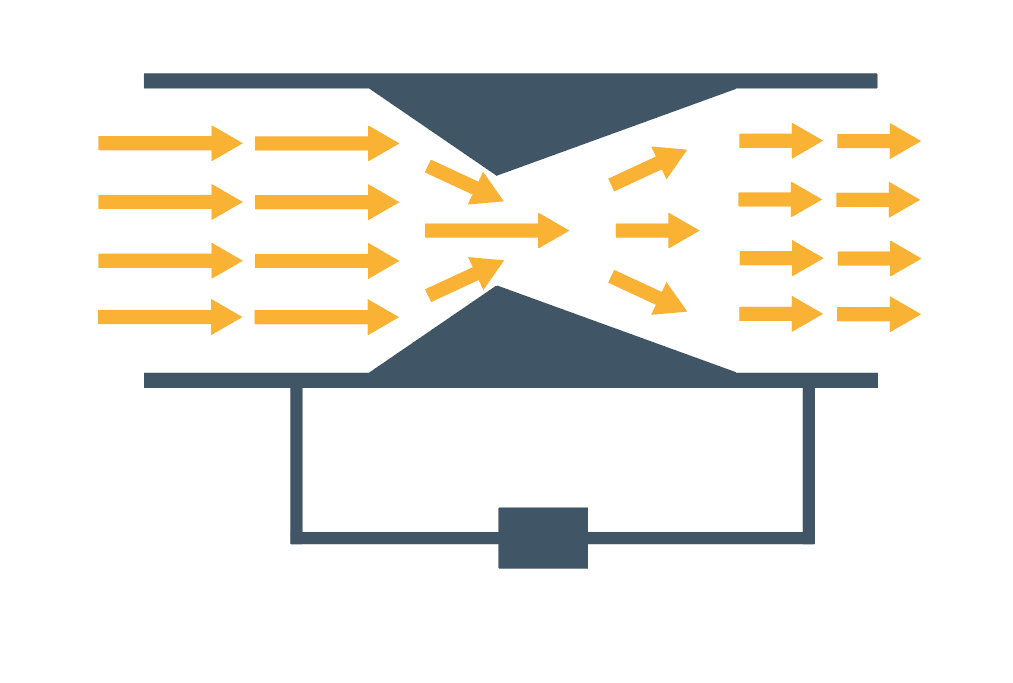

Our devices are designed for differential pressure measurement over a patented restriction. This reduces the amount of pollution significantly since the air in the measuring tube does not move. Through the years, we have also designed a uniquely shaped restriction, which gets polluted much less compared to a standard orifice plate.

Small amounts of dust can still enter the measuring tube, but the tubes are equipped with automatic compressed air purges, that are periodically activated to avoid pollution. This ensures the accuracy of the measurements. With automatic purging, there is also less need for maintenance.

Limited pressure loss

We measure differential pressure over a restriction (orifice plate). Usually, this restriction causes a significant loss in pressure. We have designed a uniquely shaped restriction that causes less turbulence and can therefore be smaller. This reduces the pressure loss to 1 to 2,5%. That means your ventilator has to work less hard, which in turn reduces the amount of energy it needs and increases its lifetime.

Very accurate flow rate measurements

This solution is very accurate and can measure a very large range of flow. This will help you signal problems at an early stage, so you will need fewer big interventions.

Reduce waste and save money

During the processing of solids, dust is created. This needs to get extracted. But if you extract too softly, you won’t catch enough (under-extraction). And if you extract too strongly, you create unnecessary waste (over-extraction). By measuring the extracted air, you’ll be able to catch dust particles in a balanced way. This has helped our clients save thousands of dollars.

Reduce (unpredicted) downtime

Unpredicted downtime never comes at a convenient moment. Our solution helps you prevent this risk in several ways:

- With our device, we only need to measure static pressure and don’t need to do anything mechanical in the pipeline. Because of this simplicity, there is less that can break.

- You don’t need to interrupt your processes to replace or inspect our measurement units. They have quick connections on both sides, which enables you to easily detach and reattach them.

- Our solution isn’t placed within the pipeline but at the end of it. Therefore it will not cause clogging or downtime due to failure.

ATEX Zone compliant

Our solutions are ATEX Zone compliant. All ATEX zones need to have spark protection. The danger lies within the voltage. If the voltage exceeds the dielectric breakdown strength of the air and dust inside the pipe, a spark will ignite. We use low voltage measurements to mitigate the risk in all our appliances, ATEX zone or not. In combination with a.o. barriers we can guarantee the highest ATEX protection in all ATEX zones.

Optimize your processes by creating real-time insight

Use our intelligent solutions to create insights into your production process, measure where problems often occur, and take action where it matters most.

Use smart connectivity

Smart connectivity features will enable you to automate steps in your processes, based on the flow rate measurements. The possibilities are endless and we are happy to advise you.

Benefits of using Flow Rate Monitoring Solutions from JOA Air Solutions

- Exactly know what is happening in your production process in real-time

- Prevent unreliable measurements

- Reduce maintenance costs, by effectively maintaining the areas that need attention

- Transport materials using less energy, because of limited clogging and reduce costs

- Reduce the risk of explosions, by detecting and solving problems early

- Prove you have control over your processes and help bring down your insurance contribution

Flow Rate Measurement Equipment tailored to your requirements

Our flow measurement units can be adapted and customized to your specific needs. We have two standardized units ready to be assembled. The measurement equipment can be used for processes using both air and gas.