Save on Energy Costs with Energy Recovery Scrubbers

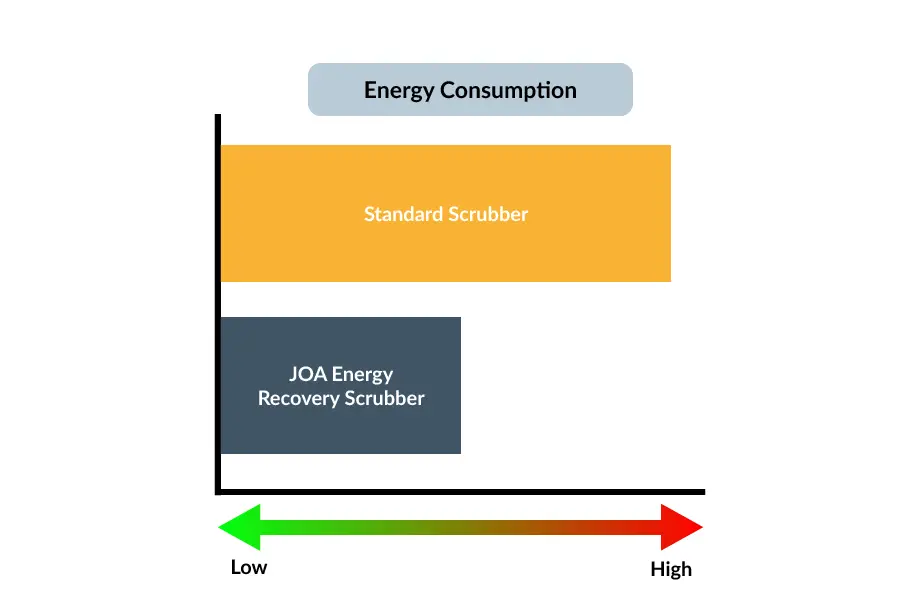

Rising costs for energy and gas are eating into your profits. That makes it more critical than ever to maintain an efficient operation in your facility. Simultaneously, you want to keep emissions under control. Because not only are we dealing with an energy crisis, we are also facing ever more stringent emission legislation. Fortunately, energy saving, cost saving, sustainability, and regulation compliance can go hand in hand. An Energy Recovery Scrubber effectively cleans your exhaust streams, which lowers unwanted emissions into the environment. Additionally, the scrubbing process extracts heat from the same exhaust stream, which can be reused in your facility.

For a large manufacturer in the FMCG industry, our Scrubbers helped reduce energy consumption by 900 kW, leading to savings of 5.9 GWh annually

JOA Client

Why choose an Energy Recovery Scrubber from JOA Air Solutions?

There are many suppliers of standardized scrubbers and heat recovery solutions, like heat exchangers. But a solution that combines the two is rare. And there are many more reasons why you’d want to implement JOA’s Energy Recovery Scrubbers:

- We use unique air technical modeling to create the most efficient solution for your situation

- Our solution enables you to recover low-grade waste heat.

- You’ll be able to clean emissions, while also connecting heat providers to energy consumers

- Up to 99,9% efficiency for our Inline Venturi Scrubbers (at 10 micron or higher)

- The self-cleaning Inline Venturi beds remove dust efficiently

- High maintenance condensers can be replaced (no fouling & freezing risk)

- The solution requires little energy and consumables

- Option to add a second stage odor removal

How industrial scrubbers work

Industrial processes generally produce exhaust streams which often contain unwanted byproducts and pollutants. In many cases, untreated exhaust streams can be harmful to the environment and human health. Industrial scrubbers efficiently remove pollutants from within the exhaust stream.

Inside the scrubber, the exhaust stream comes into contact with liquid droplets (e.g., water or other solvent), in which unwanted substances are dissolved. As a result, the exhaust stream is stripped of harmful gasses, particulates, solids, and fumes. After this process, the exhaust stream can be safely released into the environment.

JOA Energy Recovery Scrubber

The JOA Energy Recovery Scrubber is an Inline Venturi Scrubber, a type of wet scrubber. Wet scrubbers introduce a scrubbing liquid (usually water) to the dirty exhaust stream. This is done with water spray nozzles that create tiny droplets. The Venturi Scrubbers use the higher velocity of dust particles and water droplets to mix and entrap the pollutants.

How our scrubbers purify your exhaust streams

A typical Venturi Scrubber is made up of three sections. A converging section, a throat, and a diverging section. In a nutshell, this is how a Venturi Scrubber works:

- The exhaust stream first enters the converging section. Due to the gradual decrease in the cross section area, the flow velocity increases to maintain the same flow capacity.

- The flow velocity is the highest in the throat section, where scrubbing liquid is injected. The high velocity of the exhaust stream enhances its turbulence mixing with the scrubbing liquid, resulting in the formation of small droplets.

- Unwanted substances and particulates in the exhaust stream are either absorbed or carried away by the liquid droplets.

- The contaminated droplets are removed from the exhaust stream, for instance, using a cyclonic separator. The clean gas exits the scrubber, while the scrubbing liquid is reused after going through a filtration stage.

Venturi Scrubbers are often used for medium and high fume concentrations. They are especially efficient for processes producing solidifying fumes or combinations of fumes and dust. JOA provides tailor-made Inline Venturi Scrubbers that are conformant to industrial standards. The scrubbers are designed for low energy- and water/reagent consumption and can be equipped with bio-fouling control. In order to recover the wastewater coming from the scrubber, a treatment solution would be needed. We’re happy to advise you with effective and efficient solutions for this purpose.

Improve with JOA Air Solutions

How our scrubbers recover energy

During the scrubbing process, the scrubbing liquid not only captures pollutants or vapors, but also absorbs heat. Hence the Inline Venturi Scrubbers can also function as heat recovery equipment, especially if the exhaust stream has a relatively high temperature. Lowering the temperature of the exhaust stream during the scrubbing process would also enhance the absorption of vapor into the scrubbing liquid.

The heat captured by the scrubbing liquid can be recovered using a heat exchanger. That heat can then be reused by other consumers within or outside of the plant, enabling a more economical plant operation.

Our Energy Recovery Scrubbers are often employed to economize heating utilities in offices, factories, and other process equipment, especially where hot water is in demand. The recovered heat can be processed further, depending on specific needs, with additional equipment such as:

- heat pumps

- absorption chillers

- low-temperature electrical generators

- thermal energy storage systems

With an intelligent automation system, the Energy Recovery Scrubber adapts to the factory operating conditions while requiring minimum interaction from operators.

Energy Recovery Scrubbers tailored to your requirements

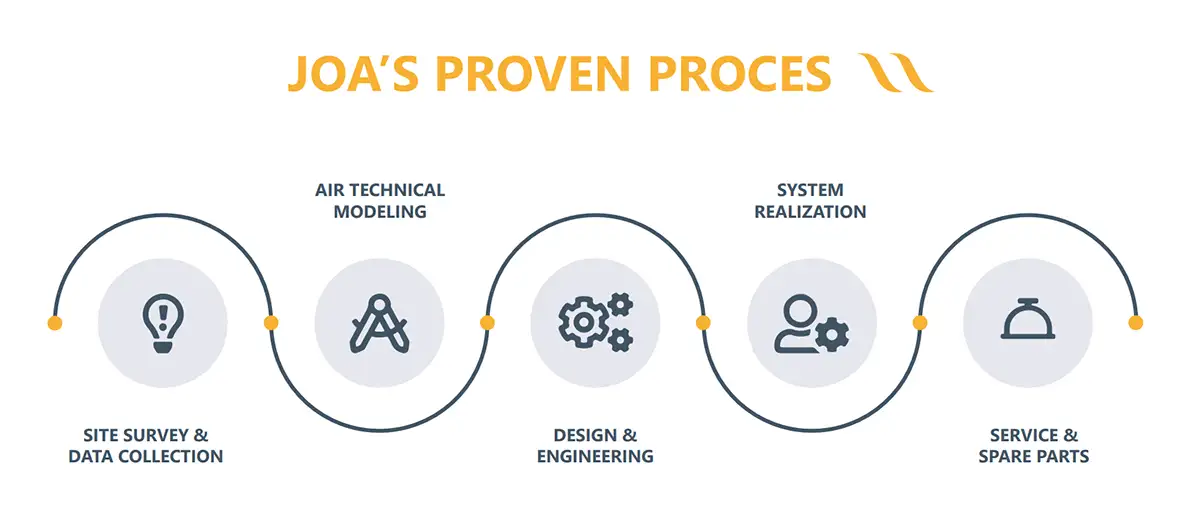

JOA offers a concrete plan for realizing the most optimal solution tailored to your needs, for both emission control and energy-saving:

- Site Survey: our engineers will gather information on site as the basis for the engineering study.

- Design, Engineering and Implementation: our in-house specialists work together to create a tailored solution, from conceptual design to project supervision.

- Day-one results: after commissioning, our Energy Recovery Scrubber will reliably keep the exhaust emission level in check while also performing heat recovery to lower energy costs.