Improper ventilation can make it difficult to enact indoor climate control. The indoor temperature, humidity, or pollutant level can make it unpleasant to work efficiently. Furthermore, improper ventilation causes uncomfortable working environments that may directly or indirectly influence workers and the quality of products manufactured. So, optimizing the indoor climate is essential to ensure long-term work efficiency and product quality.

Usually, the wet bulb globe temperature index (WBGT index), a composite temperature, is used to estimate the effect of temperature, humidity, infrared radiation, and wind speed on the human body. It is a good indicator to determine appropriate exposure levels in the work area. In an industrial environment, it also represents the heat load the “operator” experiences. The American Conference of Governmental Industrial Hygienists (ACGIH) even sets limitations in units of WBGT and provides guidelines for limiting heat strain. These are regulations you have to follow to improve improper ventilation systems.

Techniques to improve indoor climate control

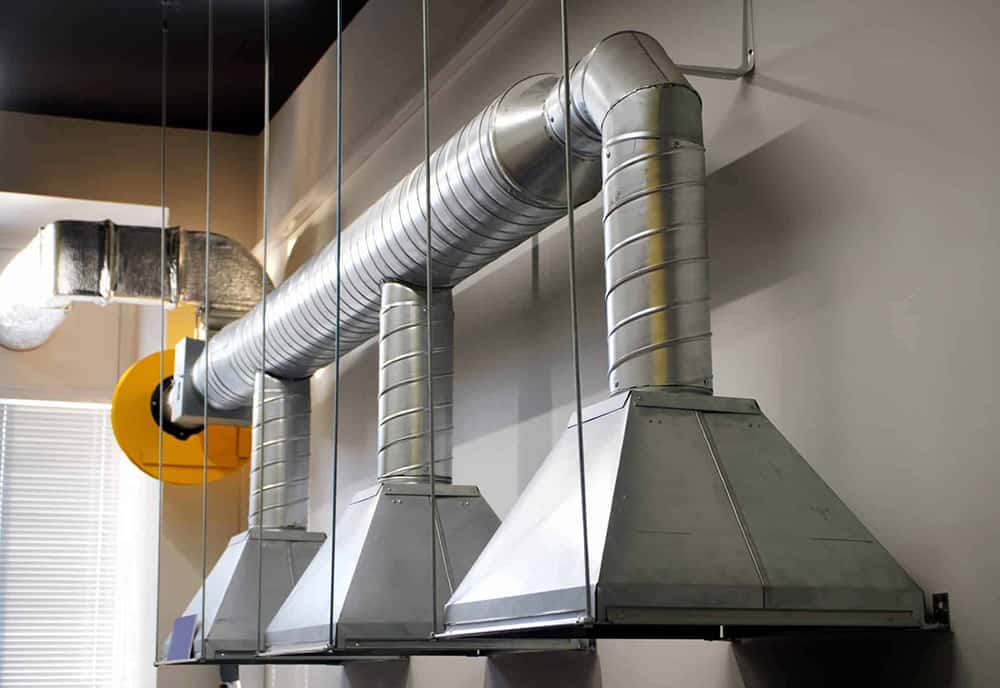

There are some techniques that can reduce excessive heat exposure and control humidity levels. It is effective to insulate hot surfaces to minimize the exchange between the source of heat and the workplace, for example, using sheets to cover hot surfaces to reduce the radiant heat emission. Implementing ventilation and air conditioning in the workplace requires smart solutions to control cost. In applicable cases JOA has installed evaporative cooling in combination with high-induction cool-jets as an economical solution.

When temperatures are high and little fresh air flows in, the humidity indoors may increase. So, humidity control and adequate refreshment air rates are basic considerations for a good working environment. Make sure that your indoor climate control functions well and receives regular maintenance.

How can JOA innovative air treatment make a difference?

JOA provides a range of smart solutions for improving the indoor climate control quality in production areas in a strategic, cost-effective manner. Our design addresses a significant reduction in WBGT. This results in local temperature reduction of 4-10°C and humidity reductions ranging from 8-20%.

JOA has developed the cool-jet, which uses secondary-air induction cooling. It has proven very effective in distributing cool air (from ventilation, HVAC, or evaporative cooling) into the targeted areas and working zones. Prior to installation, JOA models these systems. Additionally, JOA provides a process guarantee for indoor climate control.