Odor pollution can exist in factories or come from plant exhausts. Consequently, it can be a physical danger for people and the environment. Of course, this is subject to the type of gaseous components, the concentration, and the duration of the exposure. Nevertheless, odor emissions can range from a nuisance to a long-term exposure hazard. JOA provides innovative technology such as activated carbon diamond filter housings and JPCO photocatalytic oxidation filters to eliminate odor pollution.

Environmental pollution

People can experience odor emissions as a major problem when they occur in their living environment. Furthermore, people living in the area surrounding a factory can become quite concerned when they experience strong odors. In extreme cases, this can cause people to become ill. What’s more, we see a tendency that over time, small particulates and gaseous concentrations can cause a much greater long-term impact than was originally assumed. Odor emissions can have the effect of reducing the quality of life for people living in areas surrounding a factory. Therefore, it is essential to adequately remove odors from factory exhausts.

How to reduce odor pollution effectively

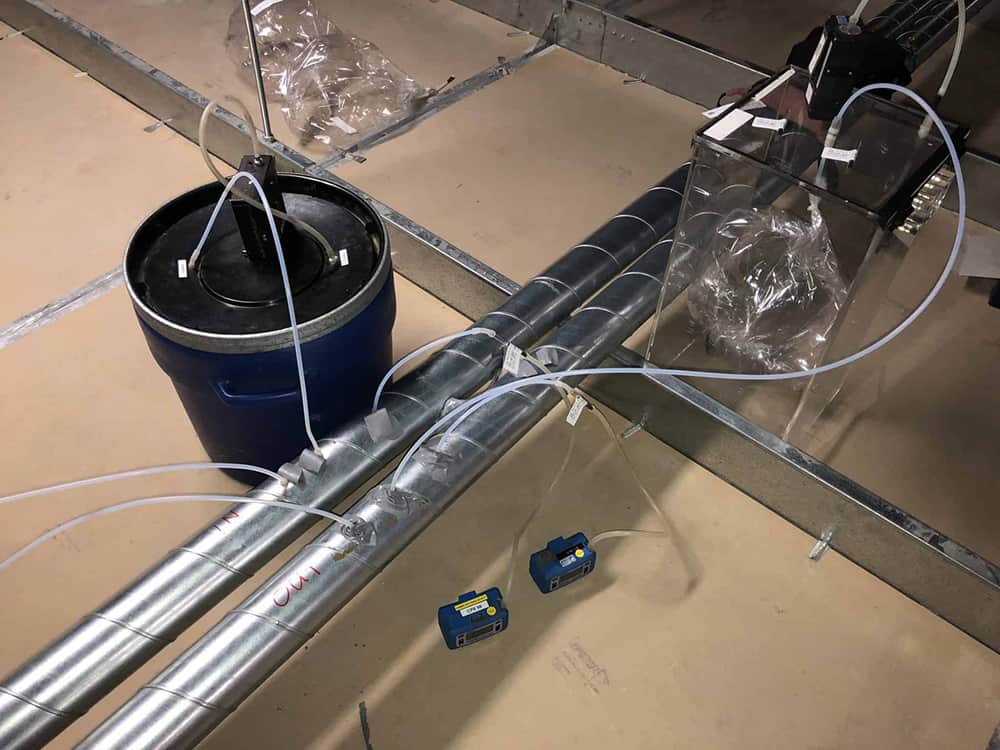

For years, we thought that we could not prevent these odors. We thought odors were something people simply had to deal with if they lived or worked next to a factory. Nowadays we know this is not necessary, and odors can be successfully and effectively removed. An odor elimination project starts with defining the odor concentration with odor sampling followed by analyses. Additionally, odor levels are quantified by dynamic dilution olfactometric analysis (odor units/m3). In the last decade, JOA has designed and installed many tailor-made odor treatment systems based on the odor concentration with compact and economical solutions, such as venturi absorption scrubbers and activated carbon and photocatalytic oxidation filters.