Don’t give harmful vapors & fumes a chance

Air Pollution, Handling Volatile Organic Compounds (VOC’s) and ineffective vapor & fume extraction leads to unhealthy and unsafe environments. Coalescer Belt Filters are able to give back control over your process by removing aerosols so Activated Carbon or Dust filters remain effective. Also, the lead to reduced downtime, and minimized risks for operators. This results in consistent emission control and Healthy, Safe industrial work conditions.

Stop guessing, start expecting by trusting on JOA Air Solutions

We do not provide standard solutions. We truly would like to understand your specific requirements before coming up with the right answers.

- Over 24 years of experience as trustworthy partner for the largest manufacturers, worldwide

- Laboratory & Field testing in advance of Design phase

- Track record of solving the most complex vapor, fumes or aerosol challenges for various industries

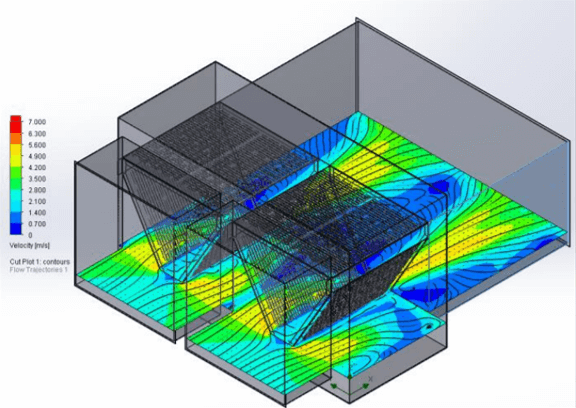

- Designed & Installed over 50 belt filter systems based on Computational Fluid Dynamics (CFD) and Air Technical Modeling

Start improving with a clear plan to extract harmful vapors

- Site Survey & Measurements

- Design based on CFD Analysis & Air Technical Modelling

- Building & Implementation

- Control over your Emissions and less downtime

By gaining knowledge of your operations in advance, we are able to guarantee results based on CFD and Modelling. This way, we have successfully designed and implemented over 450 emission control systems at manufacturers in the Chemical, Plastics, Materials, Tobacco and Food industries.

Don’t be afraid with fear for explosions, fire and unhealthy workers

Operators are the most valuable assets of a manufacturer. Managing risks regarding Fire and Explosions due to ineffective vapor extraction should be the highest priority.

Without Coalescer Belt Filters, we often encounter the following a prevent the following additional challenges:

- High Energy Consumption

- Saturation of the Active Carbon Filter

- Frequent filter changes and resources wasted on maintenance & cleaning

- Downtime

Turn your operations around and take back control of your process!

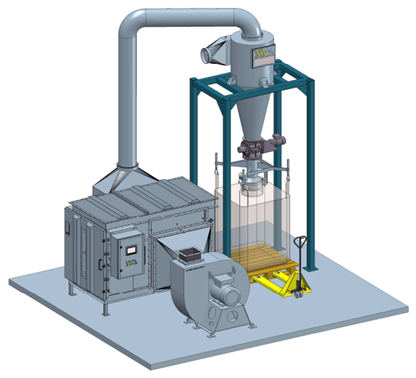

Automated Belt Filter protects Carbon Bed Units against liquid-aerosols and solidifying fumes in an efficient way. Some examples of JOA Belt Filter advantages:

- Stable and reliable vapor extraction

- 50% energy reduction compared to outdated standard solutions

- Extended lifetime of filters placed after the belt filter. Especially when handling sticky/adhesives, oily or solidifying fumes

- Easy to replace during operations and minimized filter media consumptions

- Disposal of filters in an environmental friendly way

- Automated Filtration. Less time needed by Human Resources (costs)

Before implementing the belt filter from JOA, we had frequent stops and were not in control of process, including stops to replace our Active Coal Filter. Now we have stable and reliable vapor extraction providing a healthy and safe work environment

JOA Client in the Chemical Industry

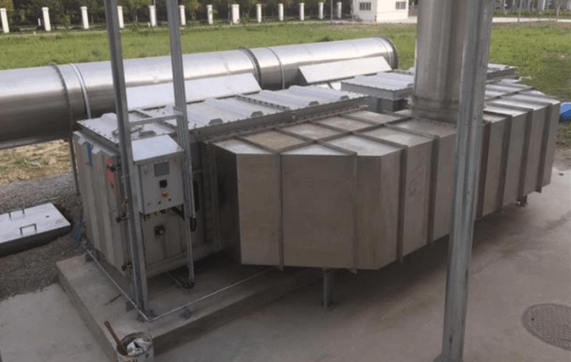

Robust, industrial solution, minimize operational risk and operator attention

All extraction systems are designed by applying proprietary Air Technical computer modelling. This design tool applies physics on multi-phase extraction systems, preventing condensation and fouling. Next to that, it minimizes the risk of fires and explosion, providing adequate input for a reliable fire extinguishing system. Before a system is designed, different scenarios are compared.

Depending on the type of application, JOA applies infrared detection sensors to activate Water, CO2, or Steam extinguishing, to be integrated in the total system design.

Replacing underperforming Dust Filters with a Coalescer Belt Filter

We often encounter situations where an existing Dust Filter is performing not well. Due to the ‘sticky’ nature of the dust, filters are clogging quickly which results in swift pressure drop increase and degrease in extraction capacity. In addition frequent filter changes and maintenance are required.

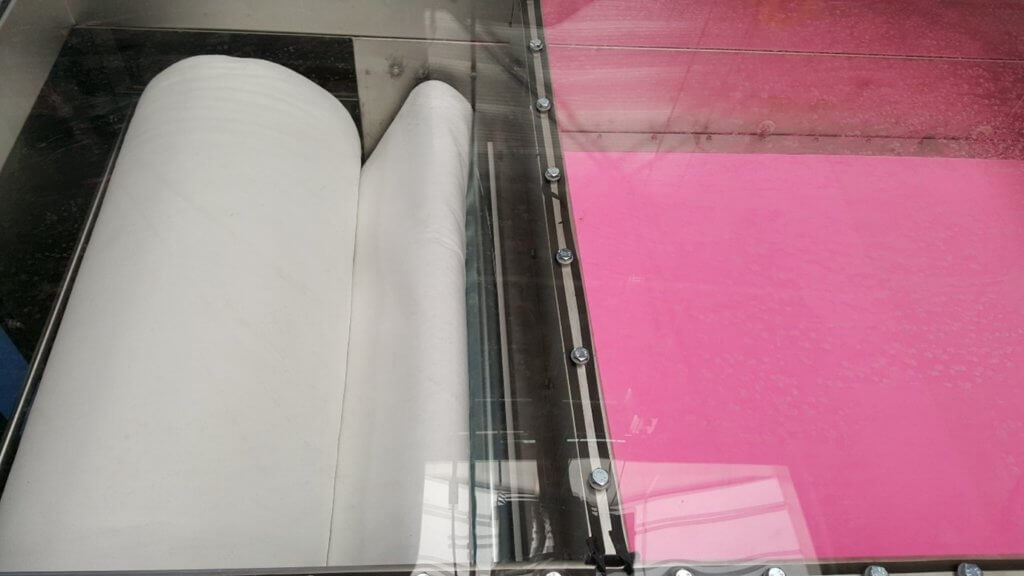

By installing a JOA belt filter system to replace the existing dust filter, many issues are resolved. The belt filter is provided with a 80 meter filter roll and as the filter material becomes more and more polluted by dust, the autonomous belt filter will automatically renew the polluted filter cloth. Due to the stable pressure drop over the belt filter, sufficient extraction capacity is provided.

A High Performance Automated Belt Filter for vapor extraction and air pollution control offers:

- Automated filtration, with minimized filter media consumption and easy to replace media

- Energy efficiency with an average ∆P, ranging (700-1250 Pa)

- Filter media consists of multiple layers providing:

- Sub-micron particulate pre filtration

- Coalescing by a mixture of fibers in the range of 10 micron, with high surface tension characteristics

- Exhaust Fiber Mat for applying shear velocity for droplet release

- The diagonal filter positioning of the belt filter creates a larger area for air to flow through and filters particulates more effectively by forming larger aerosols.

Features of a JOA Belt Filter System

JOA has designed and built over 450 Vapor Exhaust Systems with the key purpose of providing healthy and safe working conditions at industrial production sites in combination with effective and consistent emission control. The Coalescer Belt Filter for vapor extraction and air pollution control provides:

- Automated filtration, with minimized filter media consumption which is easy to replace during operation and environmental friendly to dispose of.

- Over 50% energy reduction compared to classical solutions (Average ∆P, depending on the application, ranging 700-1250 Pa).

- Modular filter set up, capable of handling 5.000 – 55.000 m3/hr. exhaust air. Belt Filters (twin set up) treating 55.000 m3 /hr. vapor exhaust streams.

Industrial Belt Filter applications:

Applying the flow pattern optimized modular V-shape traverse, combined with a wide range of advanced filter media, provides solutions in three main application fields:

- Vapor and aerosols emission control, like vapor extraction from plastics extrusion processes or Asphalt roofing coater equipment

- Vapor emissions containing sticky oil and residue traces from production. Examples are exhaust from curing ovens, Tobacco Direct Conditioning Cylinders (DCC’s), Fiber Glass, Plasticizer coating lines and adhesive spraying systems.

- Filtering and removing oily, liquid aerosols in combination with sub-micron particulate matter from VOC-laden exhaust gas streams.

Advanced CFD shear force supported coalescing:

JOA’s differentiating technology is based on applying finite element Computational Fluid Dynamics, realizing extended filter life time by shear force driven coalescing. Additionally the integrated pre separator impactor plates provide direct liquid separation and drainage.

Filter media selection for different applications:

Different filter media is applied in our series of filters. In general, all media consist of multiple layers, providing;

- Sub-micron particulate pre-filtration,

- Advanced coalescing by a mixture of fibers in the range of 10 micron, with high surface tension characteristics

- An exhaust fiber mat, applying the shear velocity droplet release, growing sub-micron size aerosols to ca. 0.1 mm droplets.

As the pressure drop of the filter media increases, new media is automatically conveyed without interrupting the production process. Up-scalable laboratory and field testing units are available to execute filter media optimization tests, or on-site performance testing.